Yokohama fenders are also called pneumatic fenders. With the development of shipping market, Yokohama fenders are widely used all over the world. They are excellent fender solution for the docks with large tidal variation. This fender allow the vessels to berth safely on any sea level.

Yokohama fenders are manufactured with high-quality and wear-resistant rubber materials. The reinforced rubber material makes it possible for Yokohama fenders to endure large compression. Even under excessive load compression, the fenders can provide low reaction force and reasonable energy absorption. The highly elastomeric rubber materials are perfect for the fenders.

To protect the fender body, several type of outer protection layers can be chosen. In different conditions, different layer can provide certain functions. No matter what type of layer, they can reduce the damage to the fender body and prolong the lifespan of the fenders.

Because the Yokohama fenders need to float on the water and to remain at certain place, installing with chain is the best installation method for them. This installation method is also economical and efficient. It can save lots of time and money for buyers on installation.

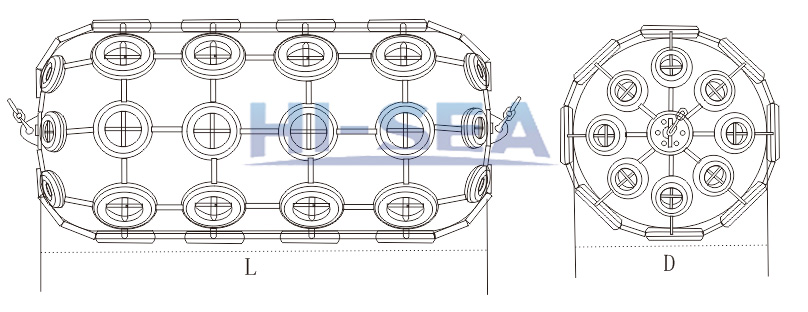

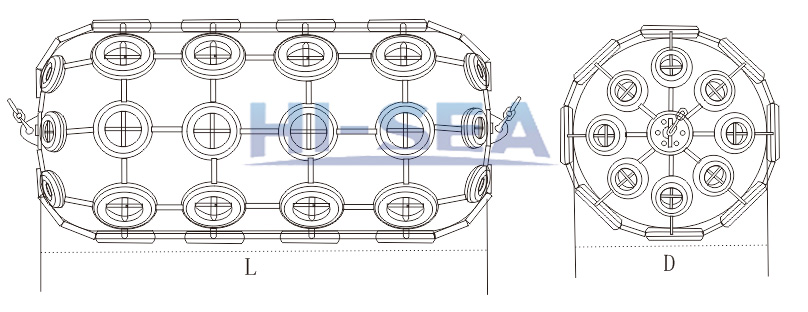

Yokohama Fenders Drawing and Dimensions:

| Fender size

D×L

(mm)

|

Initial pressure 0.5kg/cm2 |

Initial pressure 0.8kg/cm2 |

weight |

| Guaranteed energy absorption (GEA)

[kNm] |

Reaction force at GEA deflection

[kN] |

Hull pressure at GEA deflection

[kN/m2] |

Guaranteed energy absorption (GEA)

[kNm] |

Reaction force at GEA deflection

[kN] |

Hull pressure at GEA deflection

[kN/m2] |

Fender body

[kg] |

Chain & tire net

[kg] |

Total

[kg] |

| 1000×2000 |

45 |

257 |

132 |

63 |

338 |

174 |

75 |

150 |

225 |

Features:

- Low reaction force and reasonable reaction force even under excess load conditions

- Suitable for inclined berthing

- Suitable for small and large tidal ranges

- Easy and fast to deploy

- Low hull pressure

Sling Type Pneumatic Rubber Fenders(4500×12000)

Sling Type Pneumatic Rubber Fenders(4500×12000)