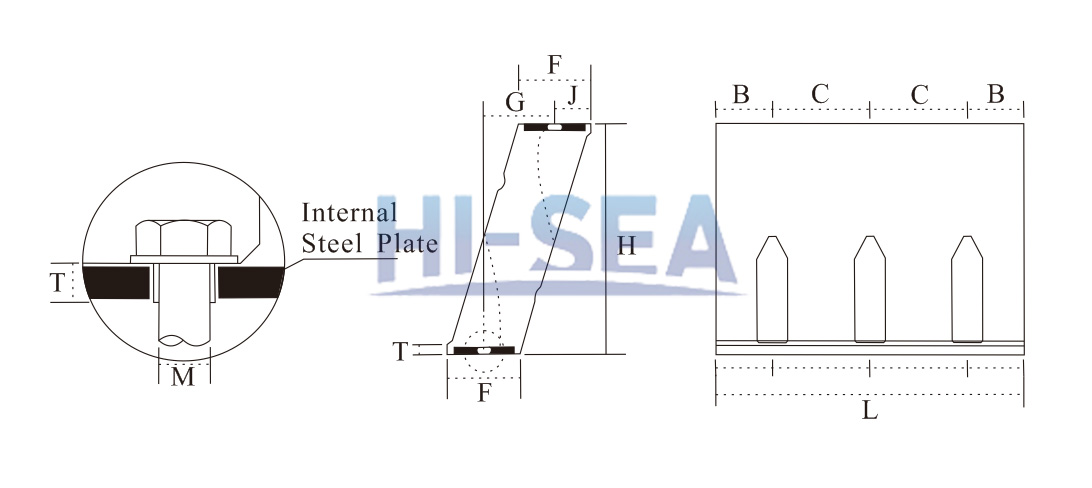

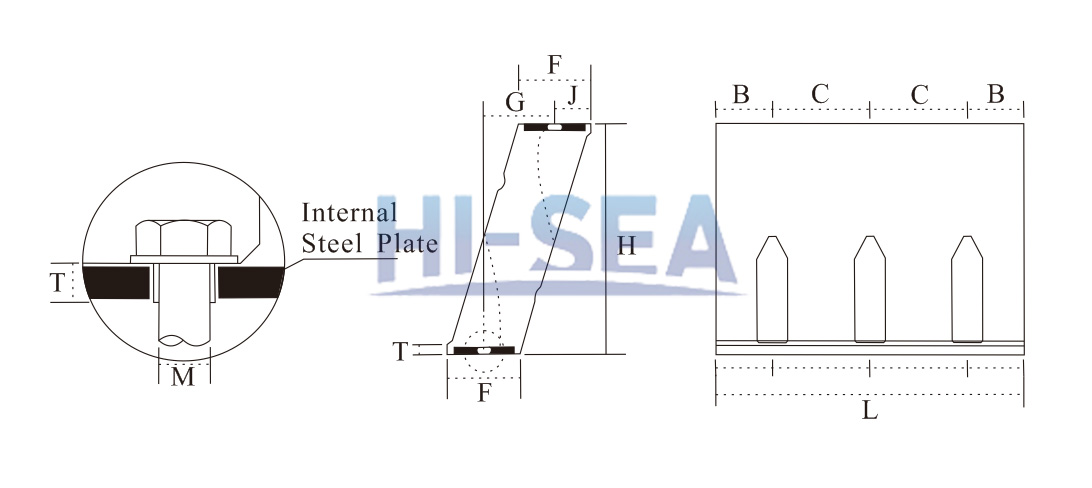

Unit Element Fender Drawing and Dimensions:

| Model |

L |

B |

C |

F |

G |

J |

T |

Holes |

| UE1250

|

800 |

150 |

500

|

401

|

388

|

202

|

35-47

|

2+2 |

| 850 |

175 |

2+2 |

| 900 |

200 |

2+2 |

| 950 |

225 |

2+2 |

| 1000 |

250 |

2+2 |

| 1050 |

275 |

2+2 |

| 1100 |

300 |

2+2 |

| 1150 |

325 |

2+2 |

| 1200 |

350 |

2+2 |

| 1250 |

375 |

2+2 |

| 1500 |

250

|

3+3 |

| 2000 |

4+4 |

| UE14

|

900 |

200 |

500

|

454

|

445

|

228

|

35-50

|

2+2 |

| 1000 |

250 |

2+2 |

| 1100 |

300 |

2+2 |

| 1200 |

350 |

2+2 |

| 1500 |

250

|

3+3 |

| 2000 |

4+4 |

| UE1600 |

1000 |

250 |

500 |

507 |

480 |

261 |

45-50 |

2+2 |

| 1100 |

300 |

2+2 |

| 1200 |

350 |

2+2 |

| 1500 |

250

|

3+3 |

| 2000 |

4+4 |

| NOTE (units:mm) |

The drawing and dimensions are for reference. Other specifications are also available. Please contact us for detailed information.

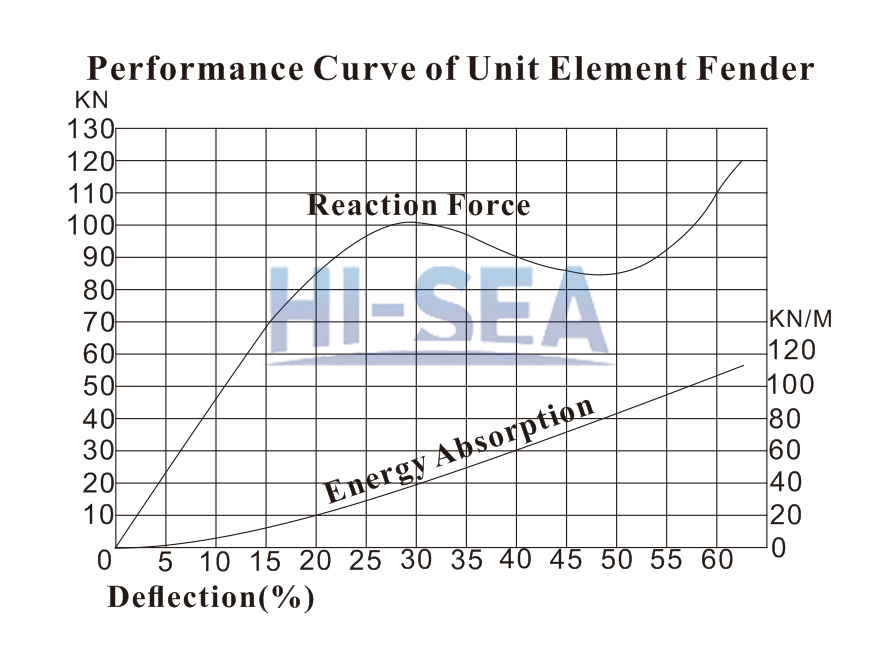

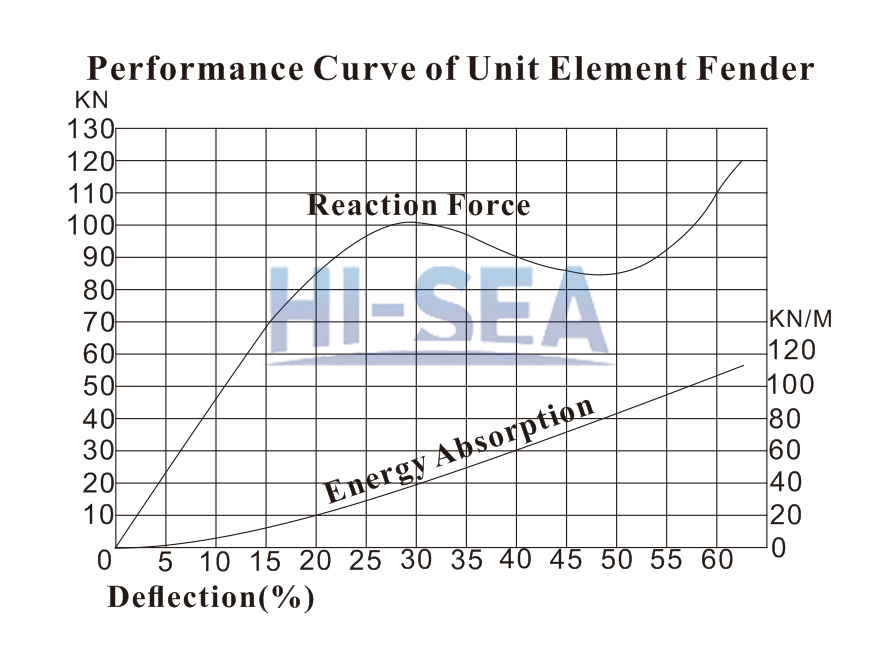

The Performance Curve of Unit Element Fender:

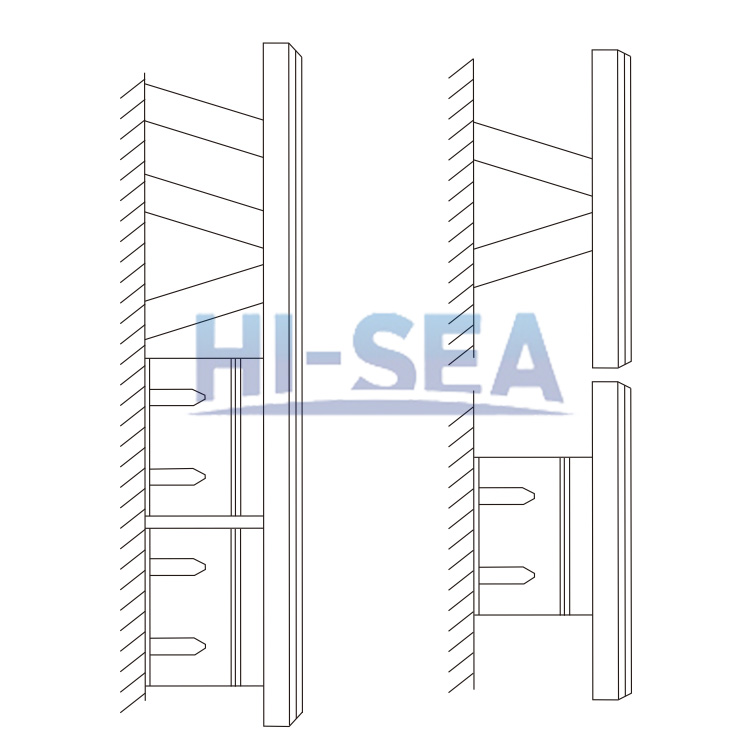

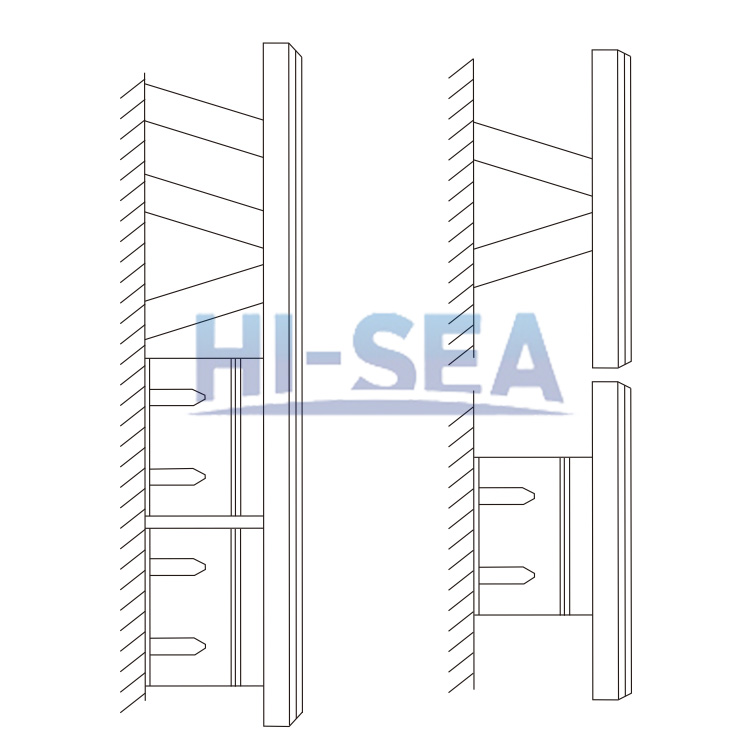

Installation of Unit Element Fenders:

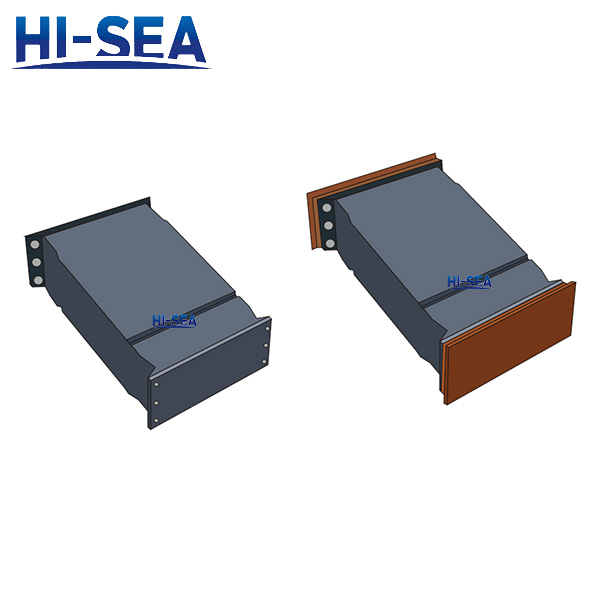

Unit Element Fenders in factory:

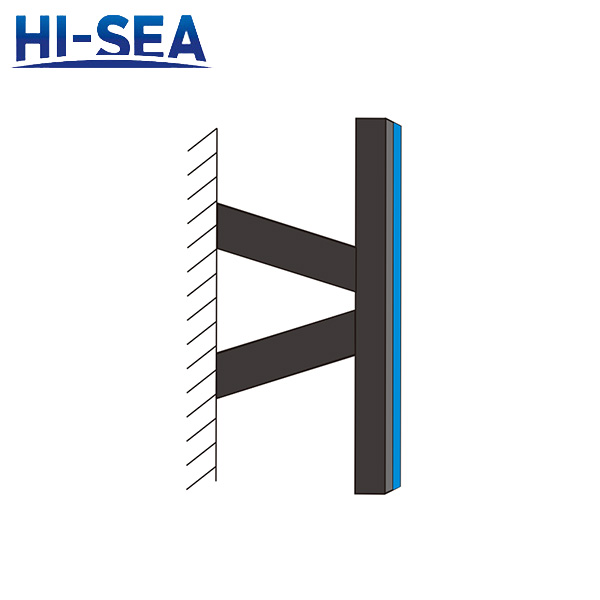

Application of Unit Element Fenders:

Introduction:

Unit element Fender is also called element fender or leg fender. The geometry of this fender is simple but provides it high performance. Designed as modular system, it is easy to install and maintain. Modular design of this fender also makes it available for frontal frame including steel panel and UHMW-PE pad. Requiring for little space to install, it can help to protect the facilities for the utmost. For many years, it has been widely used in all kinds of piers and docks.

Accessories and Fixings:

- Anchor bolts and nuts

- Bolts and nuts

- Front panel

- Face panel

Modular design, applicable for docks with limited installation space.

Sizes for all applications

High energy absorption and low wear resistance

Reasonable reaction force and shear force

Easy to install and maintain

All kinds of docks are applicable

Most dock fender systems are applicable

Performing especially well at installation space limited docks and terminals

Sling Type Pneumatic Rubber Fenders(4500×12000)

Sling Type Pneumatic Rubber Fenders(4500×12000)