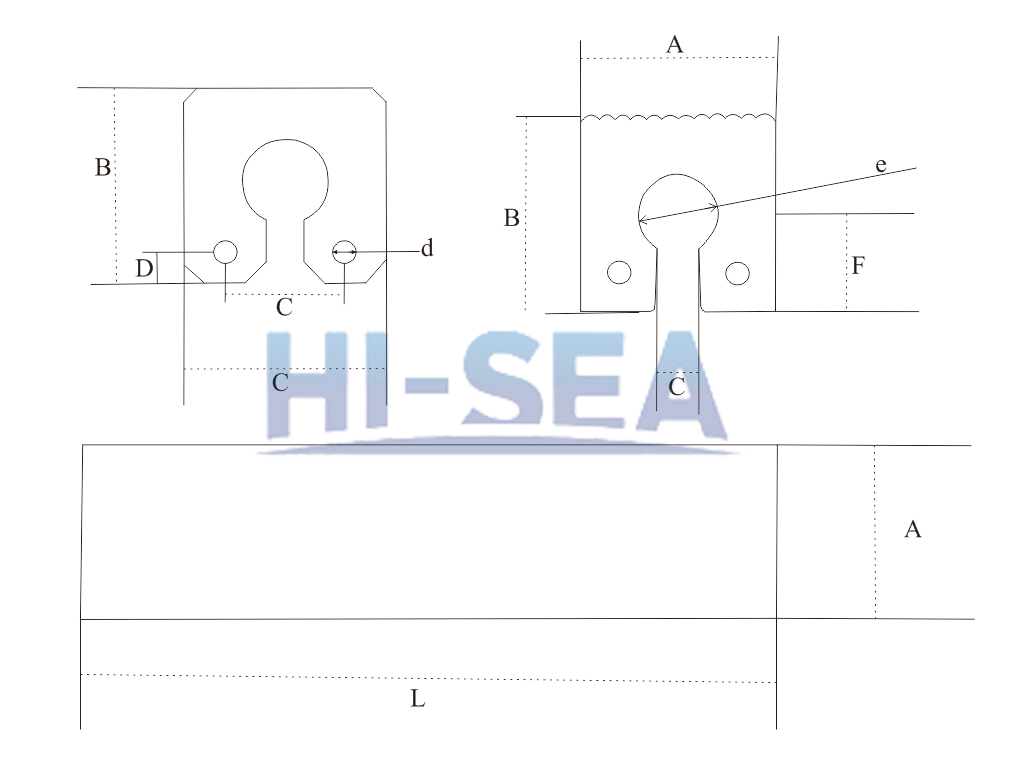

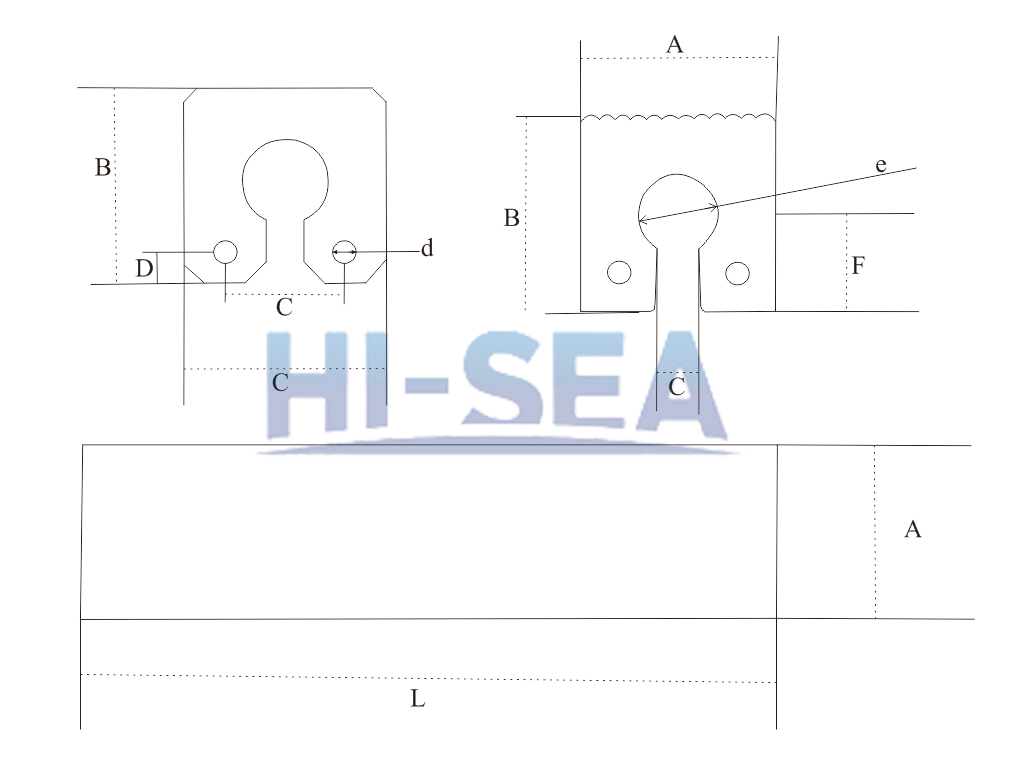

Keyhole Rubber Fender Drawing and Dimensions:

| Model |

A |

B |

C |

D |

d |

Lmax |

Weight |

| KH250 |

250 |

250 |

150 |

50 |

25 |

2000 |

56 |

| KH300 |

300 |

300 |

184 |

60 |

30 |

2000 |

86 |

| KH350 |

350 |

350 |

210 |

70 |

36 |

2000 |

122 |

| Model |

A |

B |

C |

e |

F |

Lmax |

Weight |

| KH250 |

250 |

250 |

50 |

100 |

125 |

2000 |

56 |

| KH300 |

300 |

300 |

60 |

123 |

150 |

2000 |

86 |

| KH350 |

350 |

350 |

70 |

140 |

175 |

2000 |

122 |

The drawing and dimensions are for reference. Other specifications are also available. Please contact us for detailed information.

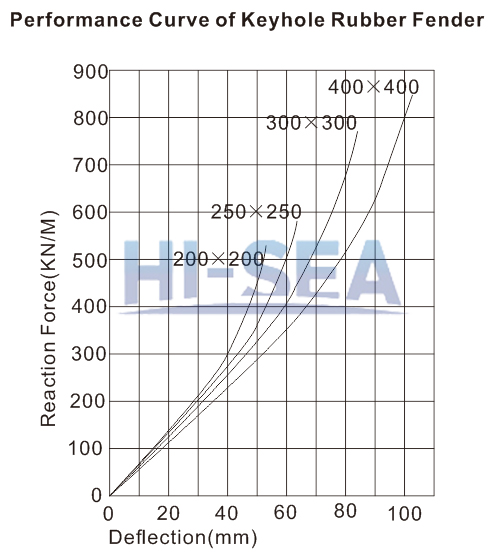

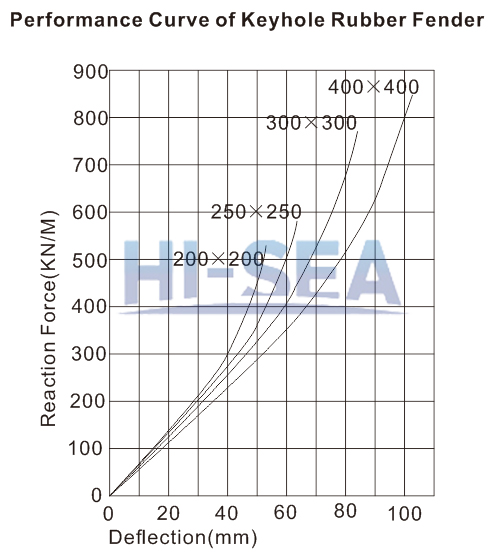

The Performance Curve of Keyhole Rubber Fender:

Installation of Cone Type Rubber Fenders:

Keyhole Rubber Fenders in Factory:

Introduction:

Keyhole rubber fender is featured with the keyhole shape opening inside. This typical profile makes it easy to install and provide it with energy absorption capabilities. Designed for tugboats and workboats, it is tough and robust. Usually it is used to protect the ships’ bow and stern. To install on the ships, bolts and nuts are needed for fixing. It can be cut and produced with curves to fit for the ship hull. It’s a highly efficient and economical solution for ship fendering.

Accessories and Fixings:

- Bolts and nuts

- Welded washers

- Intermediate support

- Mounting rod pins

- Flat bars

Sling Type Pneumatic Rubber Fenders(4500×12000)

Sling Type Pneumatic Rubber Fenders(4500×12000)