Floating fenders are designed to float on the water and can move according the rise and fall of the sea level. This design has paved the way for those docks in need of rubber fenders with large tidal variations. So, the floating fenders are popular around the world with the representative of YOKOHAMA fenders.

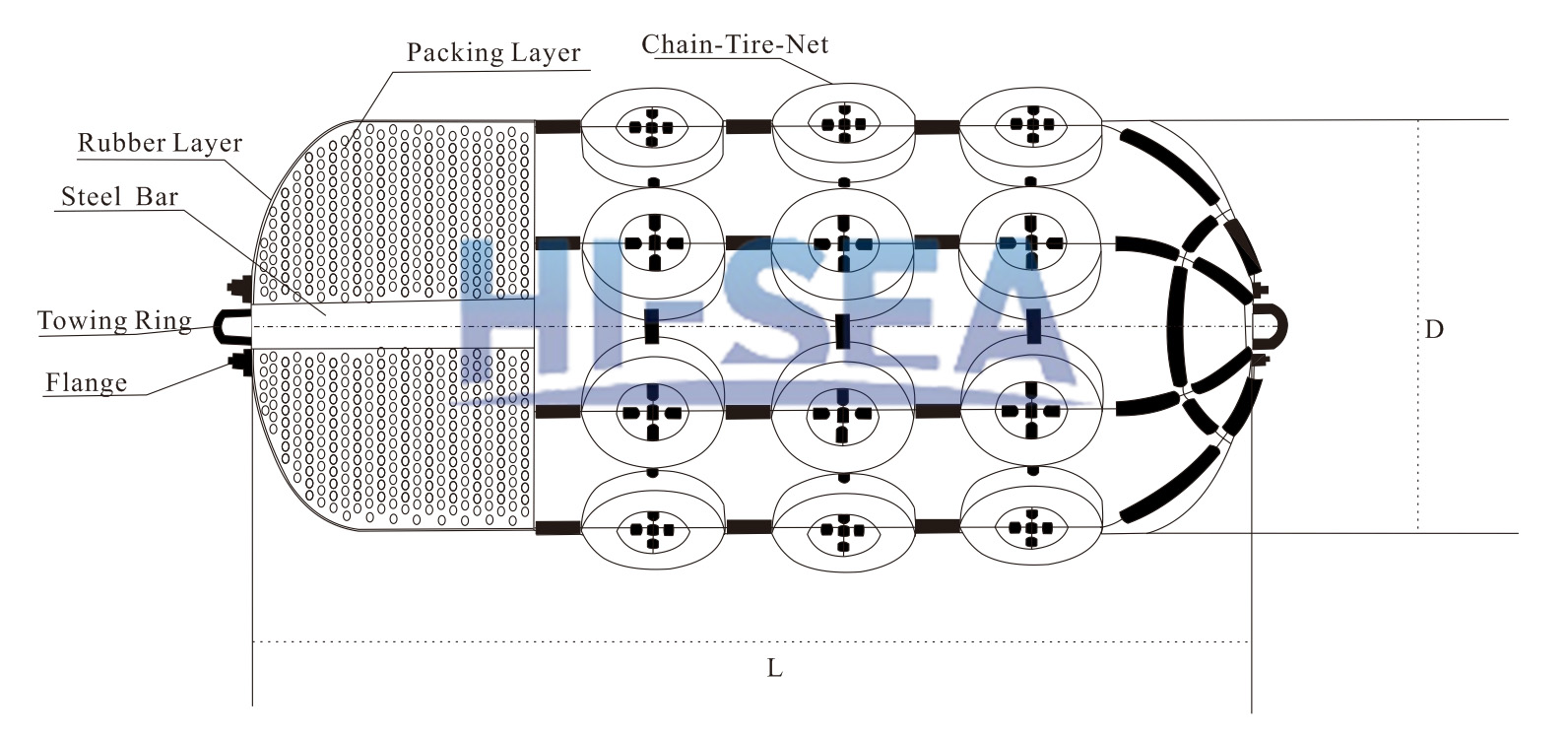

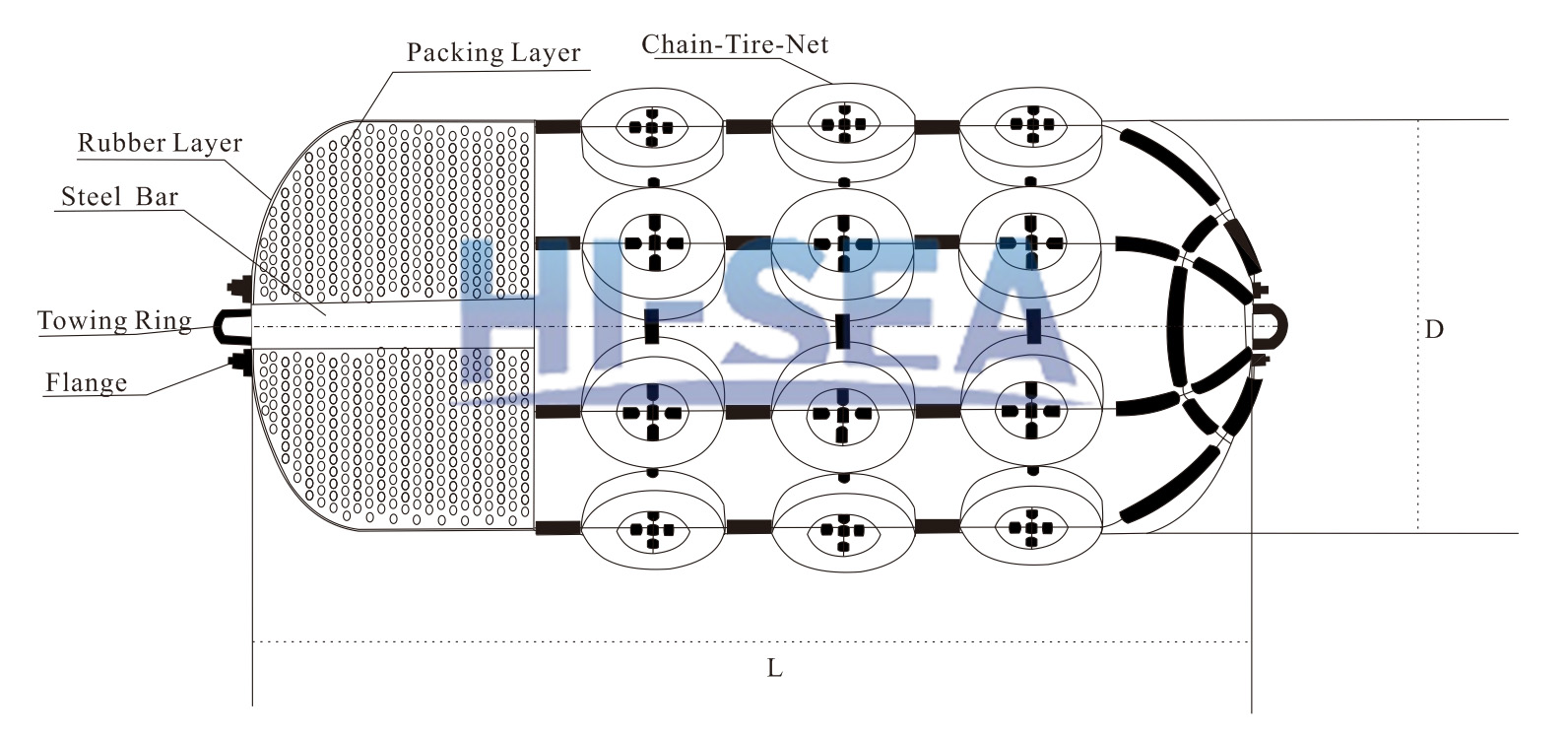

Floating fenders can be subdivided into several types, but mostly, the main body of the floating fenders are composed of rubber layer, packing layer and steel bar. The rubber layer and the packing layer form the cushion part of the fenders. The materials used are generally more elastomeric and resistant than those of fixed fenders. Even on large deflection, the floating fenders can still function well. The steel bar is used to support the whole floating fender.

The floating fenders usually are connected with chains as the installation method. The other ends of the chains are fixed onto the dock structures. This installation method helps the floating fenders to remain in the certain area without limit their flexibility.

Floating Fenders Drawing and Dimensions:

| Modelo |

D(milímetro) |

MAXIMUM DEVIATION(%) |

L(milímetro) |

MAXIMUM DEVIATION(%) |

| F700×1500L |

700 |

±4 |

1500 |

±4 |

Funciones:

- Strong against shearing force

- Good performance on inclined berthing

- Not affected by the tide

- High energy absorption and low reaction force

- Low how pressure

- Adaptable to the tide

- Easy to install and move