The model 450×370×250 has changed a lot compared with smaller standard models. The bottom plate has been designed to be a rectangle and not a square any more. The width is 450mm and the length is 520mm. Anther change of the dimension is the thickness of rubber roller. The adjustment of the steel frame is mainly to fit for the size of the target dock structures.

The cushion roller fenders can be divided into two parts. One is the rubber roller used as the cushion part and the other is the steel frame used as the supporting part. These two parts together consists of a complete fender equipment. Manufactured with high-quality materials, our cushion roller fenders can perform well in almost all application scenarios.

Cushion roller fenders are designed to be easy to install. Due the pre-drilled steel frame, the installation is not only easy but also cheap. The modular design for each part of the cushion roller fender makes the fenders easy to maintain and repair.

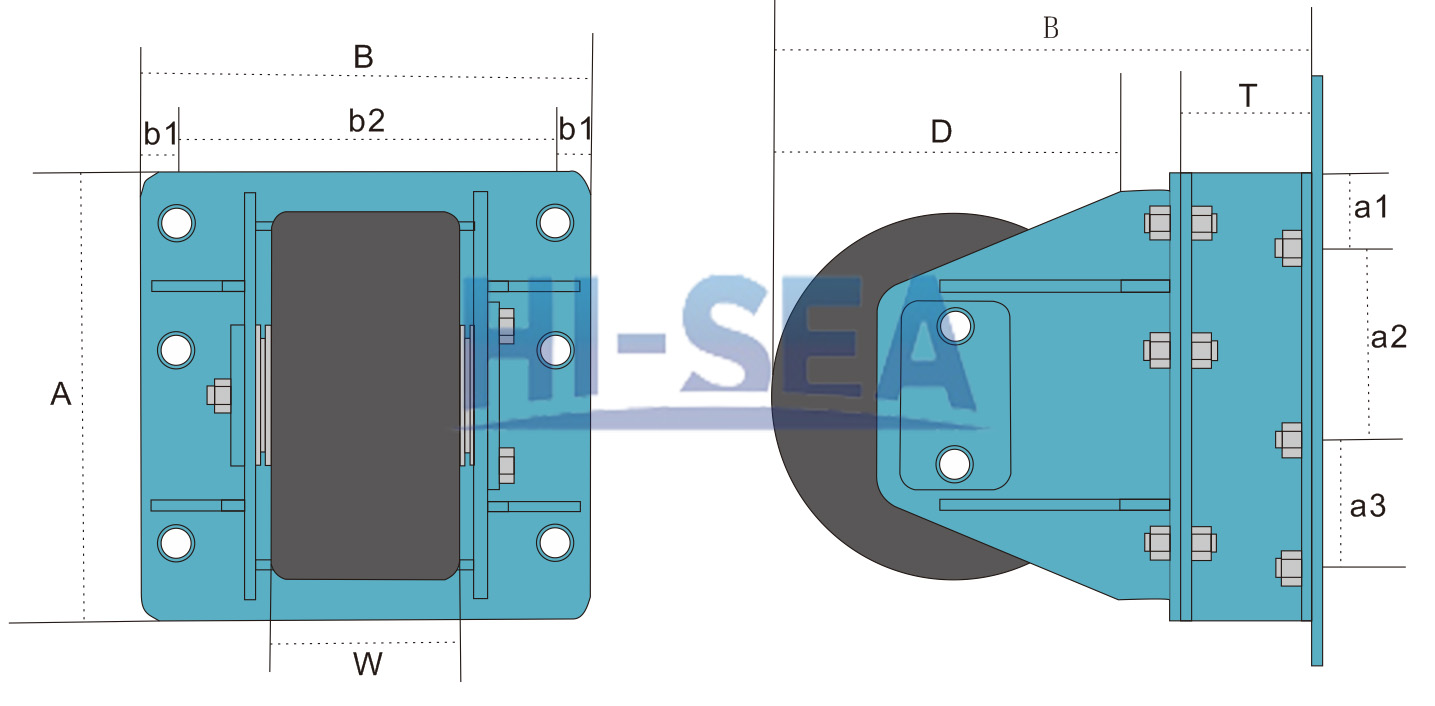

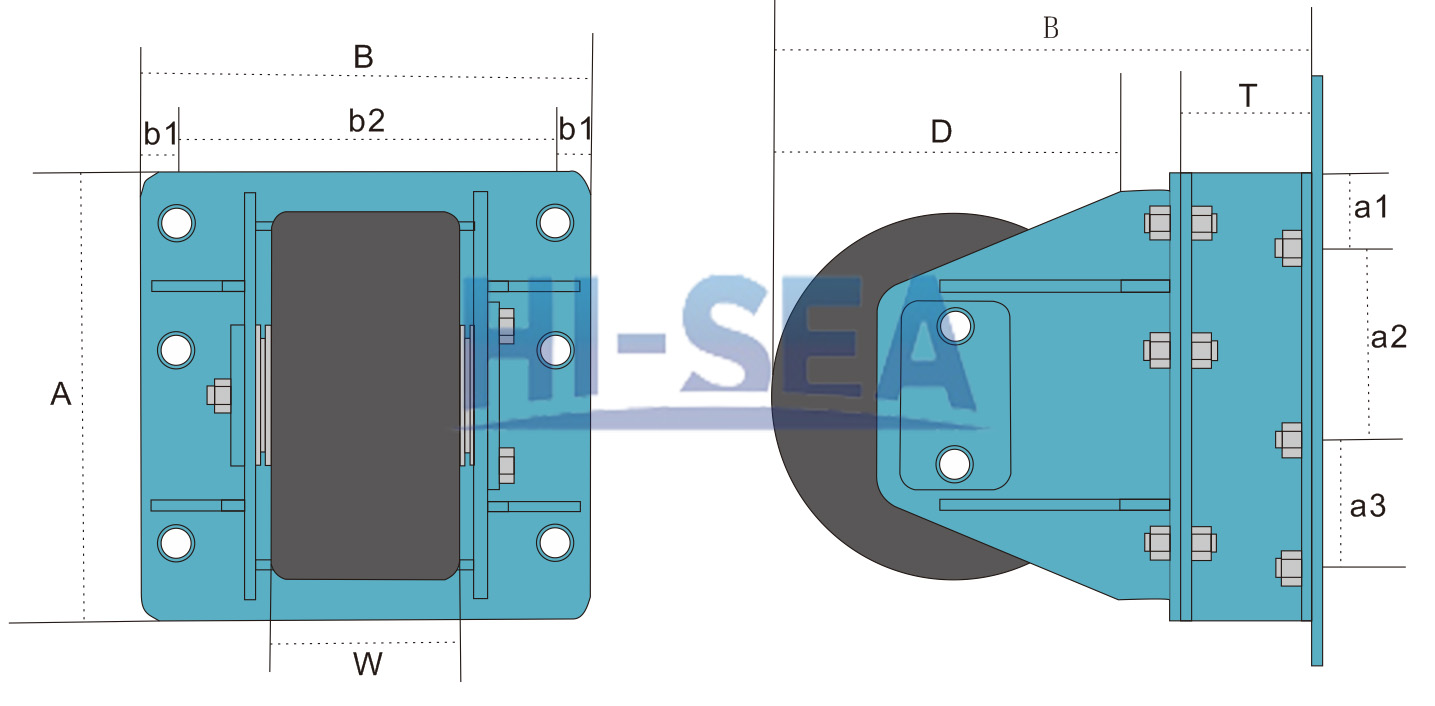

Cushion Roller Fenders Drawing and Dimensions:

| A |

B |

C |

D |

T |

W |

a1 |

a2 |

a3 |

b1 |

b2 |

Fixings |

| 450 |

520 |

546 |

370 |

130 |

250 |

80 |

160 |

120 |

50 |

420 |

6×M24 |

Funciones:

- Very quiet when working

- Low maintenance and easy to repair

- Very resilient with high quality rubber material

- Reasonable energy absorption on berthing impacts

Aplicaciones:

- Guide for pontoon pile

- Other floating structures