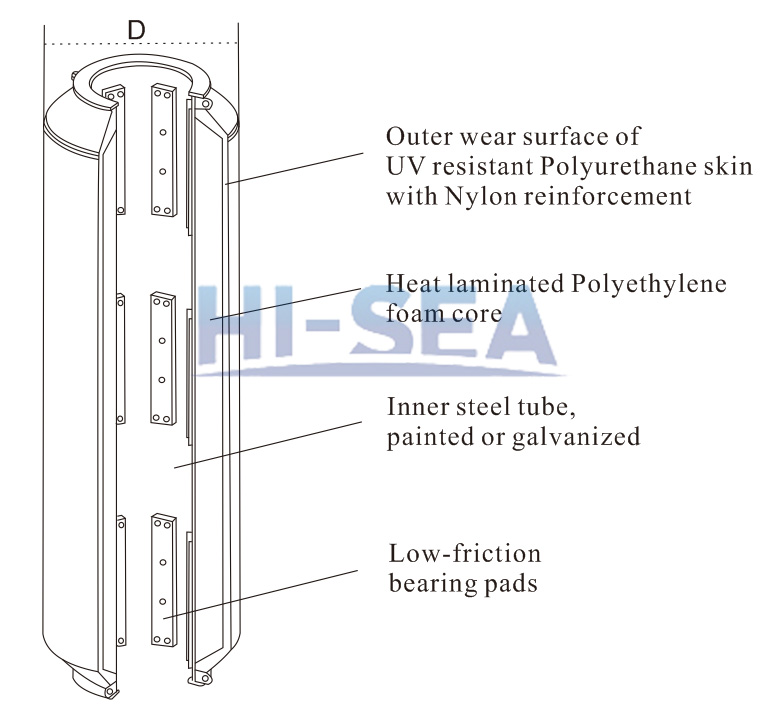

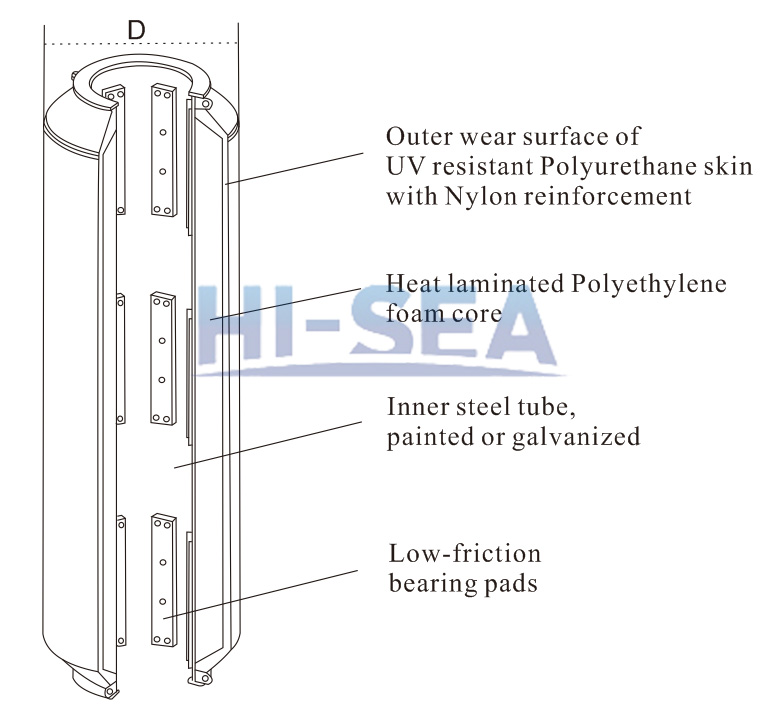

Donut Fender Drawing and Dimensions:

| Fender size

D

[mm] |

Max. Pile

Diameter

[mm] |

Standard capacity |

| Energy

[kNm] |

Reaction

[kN] |

| 900 |

457 |

2.4 |

69 |

| 1270 |

610 |

7.2 |

116 |

| 1450 |

710 |

9.2 |

131 |

| 1520 |

762 |

10.5 |

140 |

| 1780 |

914 |

14.1 |

162 |

| 1910 |

995 |

16.4 |

175 |

| 2030 |

1067 |

18.6 |

186 |

| 2210 |

1185 |

22.3 |

204 |

| 2290 |

1219 |

23.6 |

210 |

| 2490 |

1345 |

28.0 |

229 |

| 2540 |

1372 |

29.3 |

234 |

| 2790 |

1524 |

35.3 |

256 |

| 2970 |

1639 |

40.1 |

273 |

| 3050 |

1676 |

42.1 |

280 |

| 3300 |

1829 |

49.5 |

304 |

| 3450 |

1933 |

54.6 |

319 |

| 3530 |

1981 |

57.2 |

327 |

| 3810 |

2134 |

65.9 |

350 |

| 3960 |

2241 |

72.1 |

366 |

| 4060 |

2286 |

75.1 |

374 |

| 4220 |

2388 |

81.3 |

389 |

Donut Fender in Factory:

Introduction:

As a specific type of foam foam fender, donut fender is designed to slip over a stationary monopile. The fluctuation of water level makes the fender float up and down. When vessels berth and slide along the fender, it will rotate accordingly. Donut fender, according to the drawing, consists of a 100% closed cell cross-linked polyethylene foam core, a reinforced elastomeric skin and low friction pads at the internal steel core. Usually, mooring crowns, counterweights or other protection equipment can be added.

This is a highly bespoke product, almost all parameters can be adjusted on requests.

Sling Type Pneumatic Rubber Fenders(4500×12000)

Sling Type Pneumatic Rubber Fenders(4500×12000)