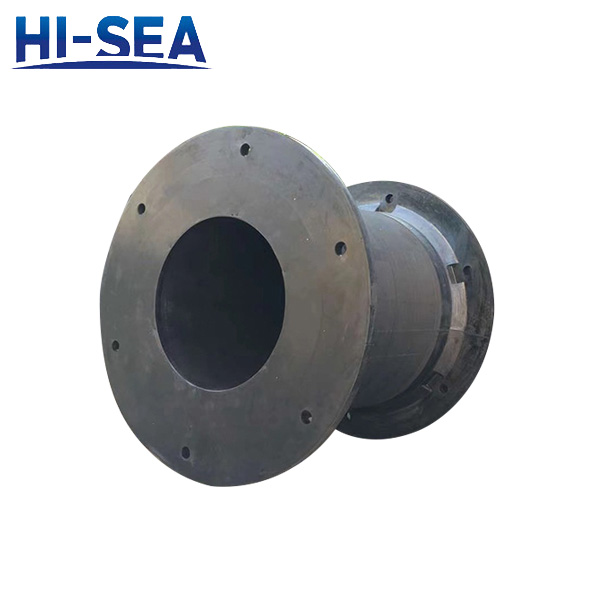

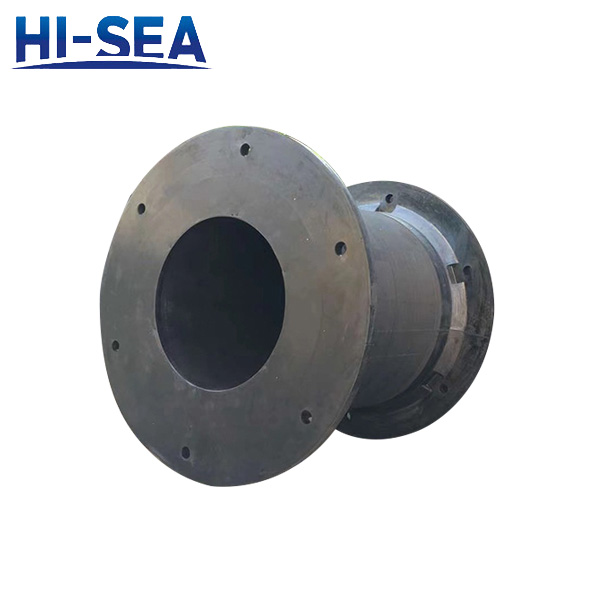

Super cell rubber fender has proven itself for decades of service. As large-size fenders, they are reliable on many heavy-duty docks and terminals. Designed as the shape of drum, super cell rubber fenders are good at energy absorption and can reduce shear forces. Equipped with frontal frame, which is usually combined with the frontal panel and UHMW-PE face pad, they fender systems can provide better performance on applications. Except for low hull pressure and friction, the system can also prolong the time for the cell fender body on service.

Most cell fenders are designed to be large in size. The SC1600, SC1700, SC2000 are middle large models of cell fenders (for other detailed sizes and information, please refer to super cell type rubber fender).

Super cell fenders are robust and resistant. After years’ using experience, cell rubber fenders proved their excellent performance in many areas, especially in terminals like container and bulk terminals, oil and gas terminals, cargo terminals, ferry and RoRo terminals, cruise terminals and so on.

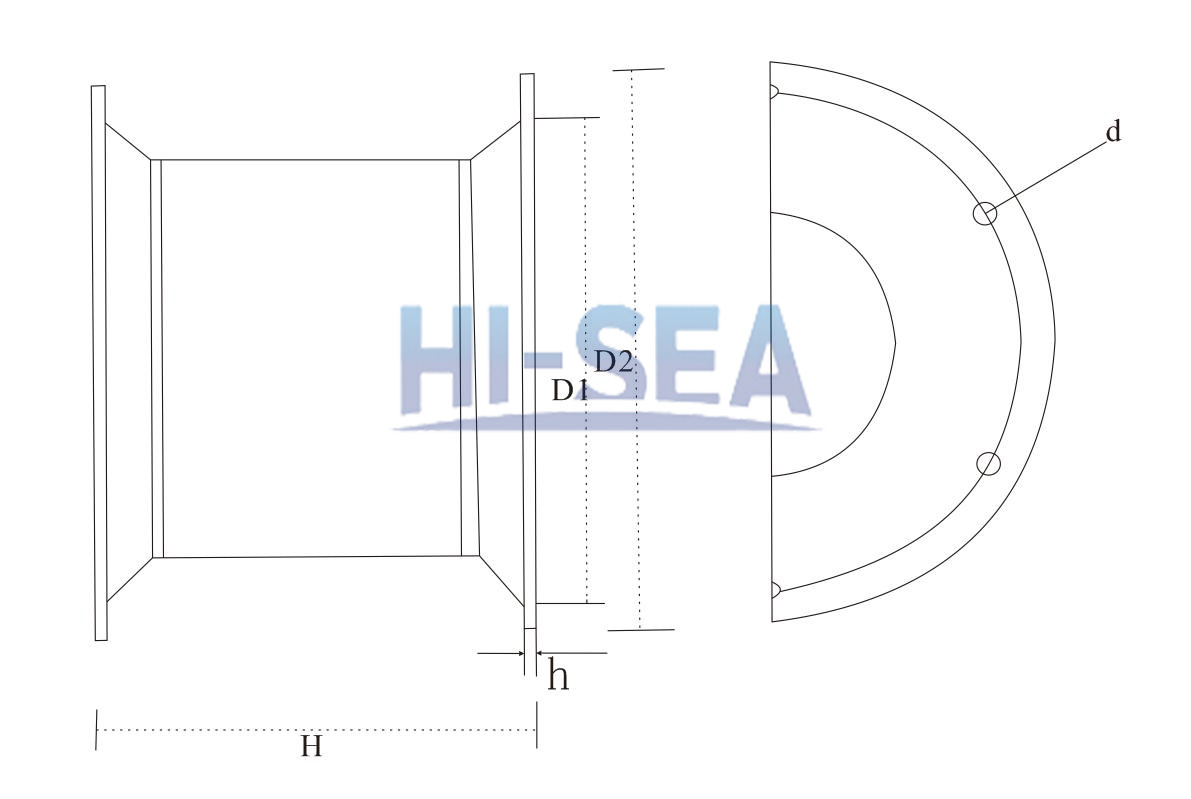

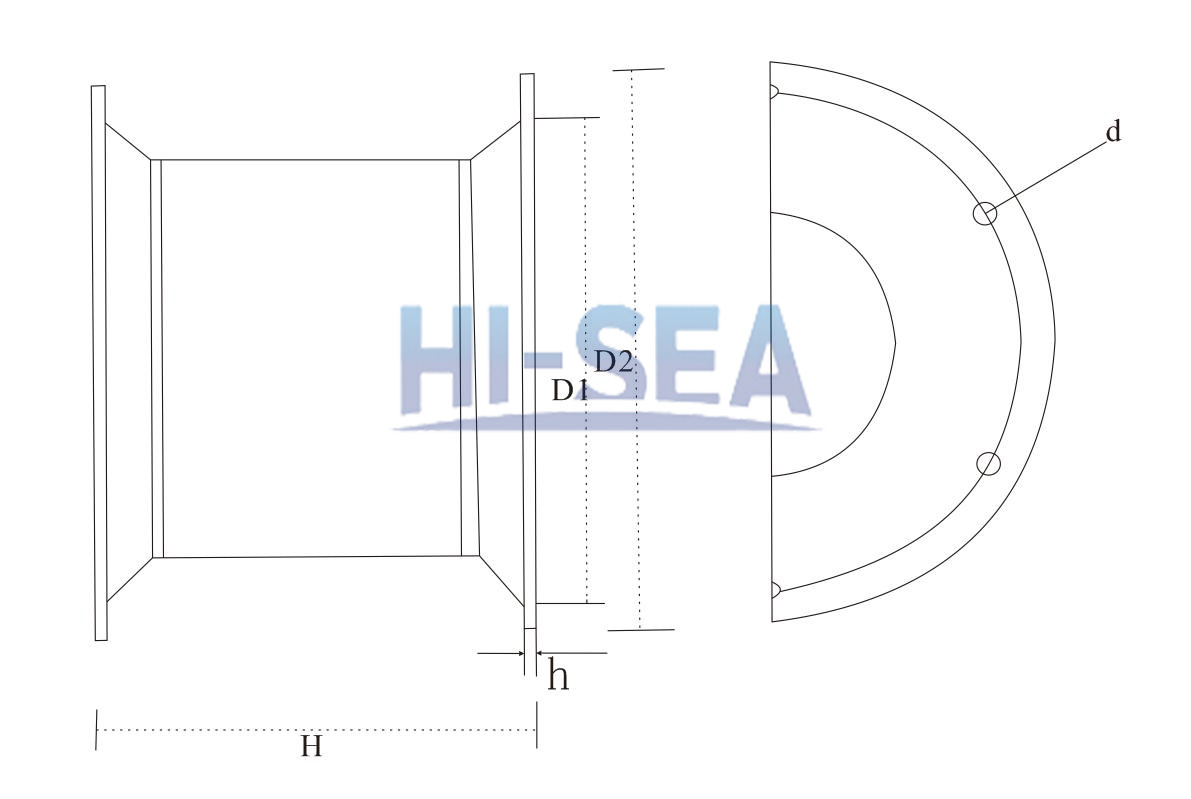

Super Cell Rubber Fenders Drawing and Dimensions:

| Modell |

H |

D1 |

D2 |

h |

n |

d |

| SC1600 |

1600 |

1800 |

2000 |

46 |

8 |

61 |

| SC1700 |

1700 |

1900 |

2100 |

50 |

8 |

66 |

| SC2000 |

2000 |

2000 |

2200 |

50 |

8 |

74 |

Performance List of Super Cell Fenders:

| Modell |

Nenndurchbiegung(%) |

Leistung |

| R(Kn) |

TOLERANZ(%) |

E(KN/M) |

TOLERANZ(%) |

| SC1600 |

52.5 |

1140.0 |

±10 |

801.0 |

±10 |

| SC1700 |

1287.0 |

960.0 |

| SC2000 |

1781.0 |

1564.0 |

Funktionen:

- Einfach zu installieren

- High wear resistance

- Lange Lebensdauer & geringer Wartungsaufwand

- Excellent energy absorption and low reaction force

- Low hull pressure, low friction and low shear forces

Fixings and Accessories:

- Frontplatte

- Face Pad

- U Anker

- Anchor Bolts

- Shear Chain

- Gewichtskette

- Spannkette

- Connecting Bolts and Nuts