Floating fenders are what they are called. They can float on the water to ensure that the vessels can berth any time needed without fearing of the tidal variations. The fender provides an excellent solution to docks with large tidal variations.

Floating fenders are designed with high energy absorption, low reaction force and low shear force. Those advantages make them better than many other fenders on performance. Floating fenders are mainly composed of three parts and the towing ring and flanges are used to seal the three parts. The sealing process requires higher technological conditions than the main body.

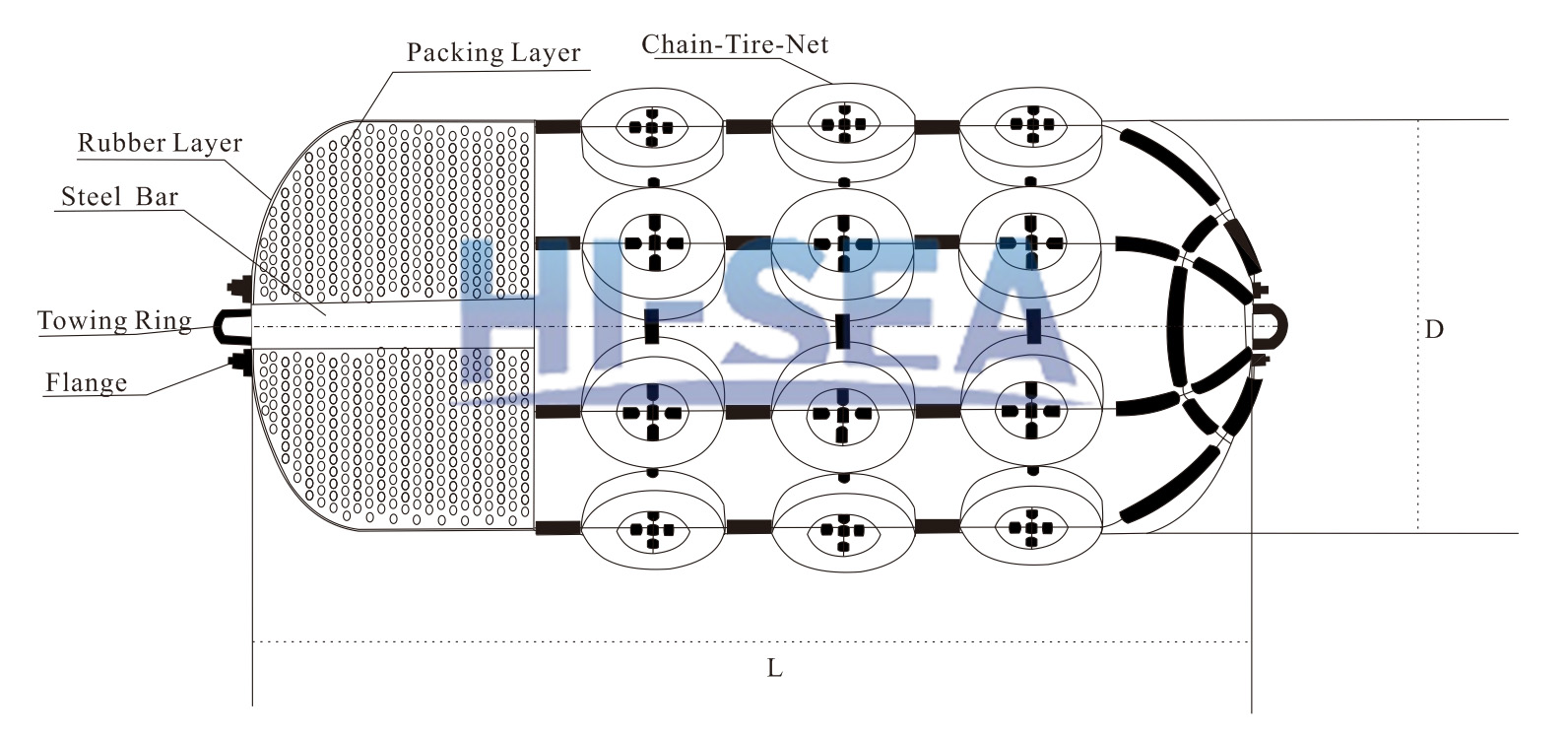

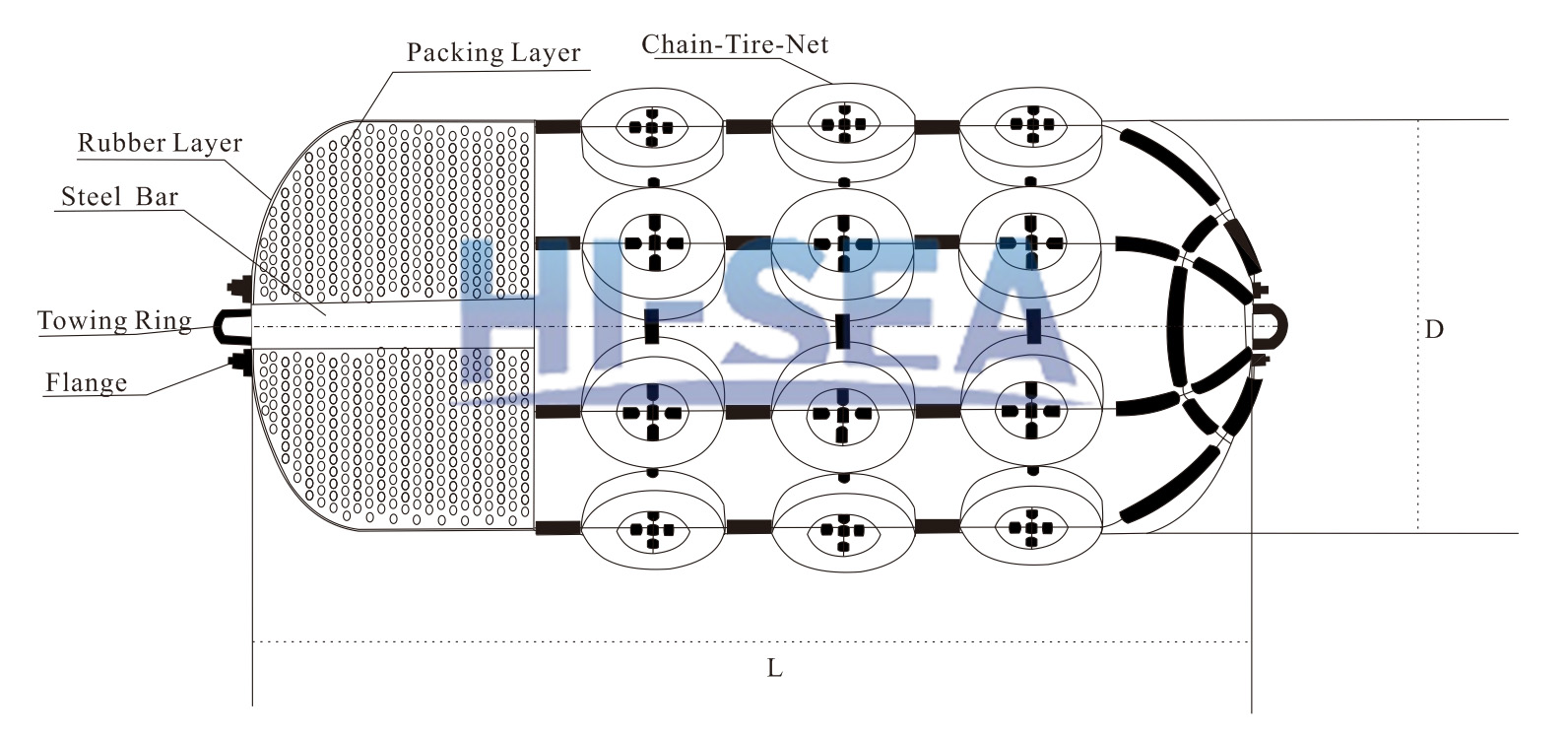

The main body of floating fenders are composed of rubber layer, packing layer and steel bar. They form the cushion part and supporting part. Large impacts can be absorbed with the cushion part manufactured with elastomeric and highly resistant materials. The fenders are generally connected with chains whose another ends are fixed onto the dock structures. This installation method fits for floating fender for it not only ensures the flexibility of the fender but also make the fender stay at the right place.

Floating Fenders Drawing and Dimensions:

| Modell |

D(Mm) |

MAXIMUM DEVIATION(%) |

L(Mm) |

MAXIMUM DEVIATION(%) |

| F1700×3000L |

1700 |

±4 |

3000 |

±4 |

Funktionen:

- Good performance on inclined berthing

- High energy absorption and low reaction force

- Low how pressure

- Adaptable to the tide

- Easy to install and move

- Not affected by the tide

- Strong against shearing force