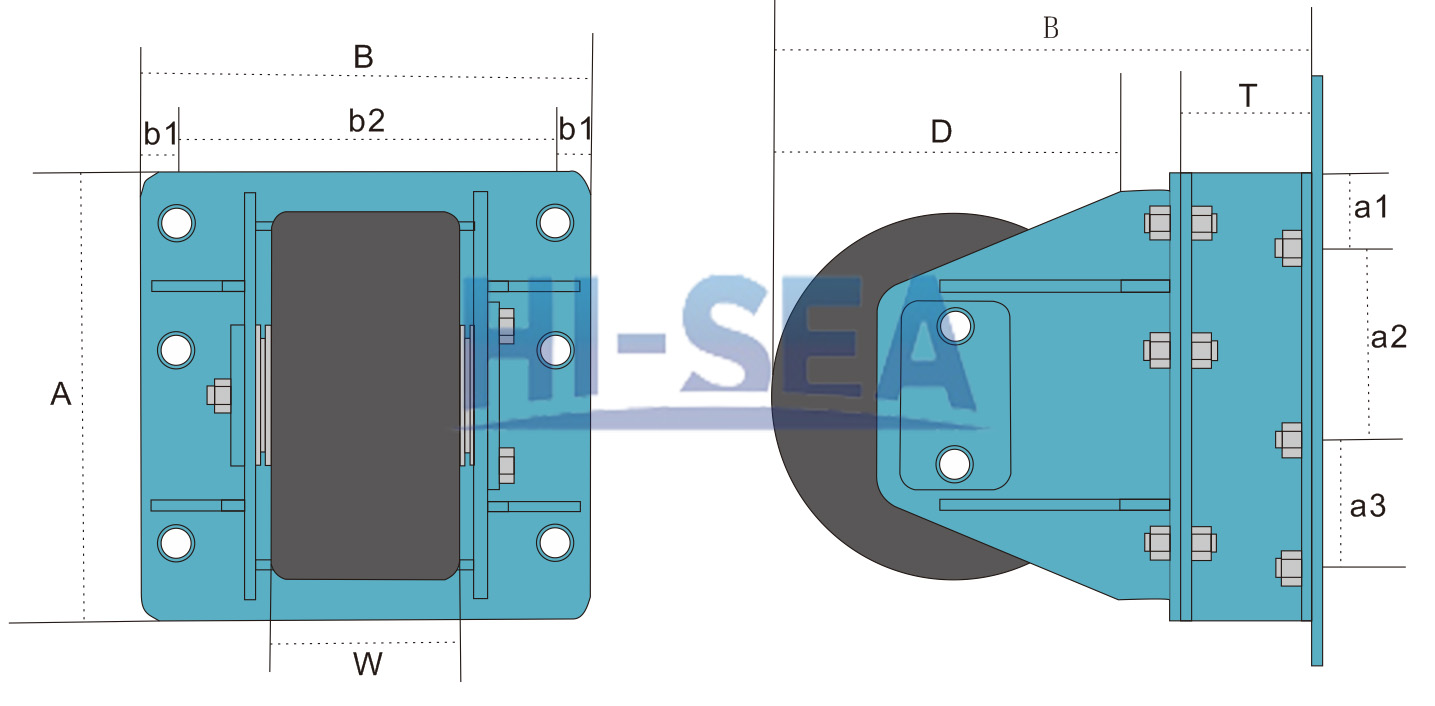

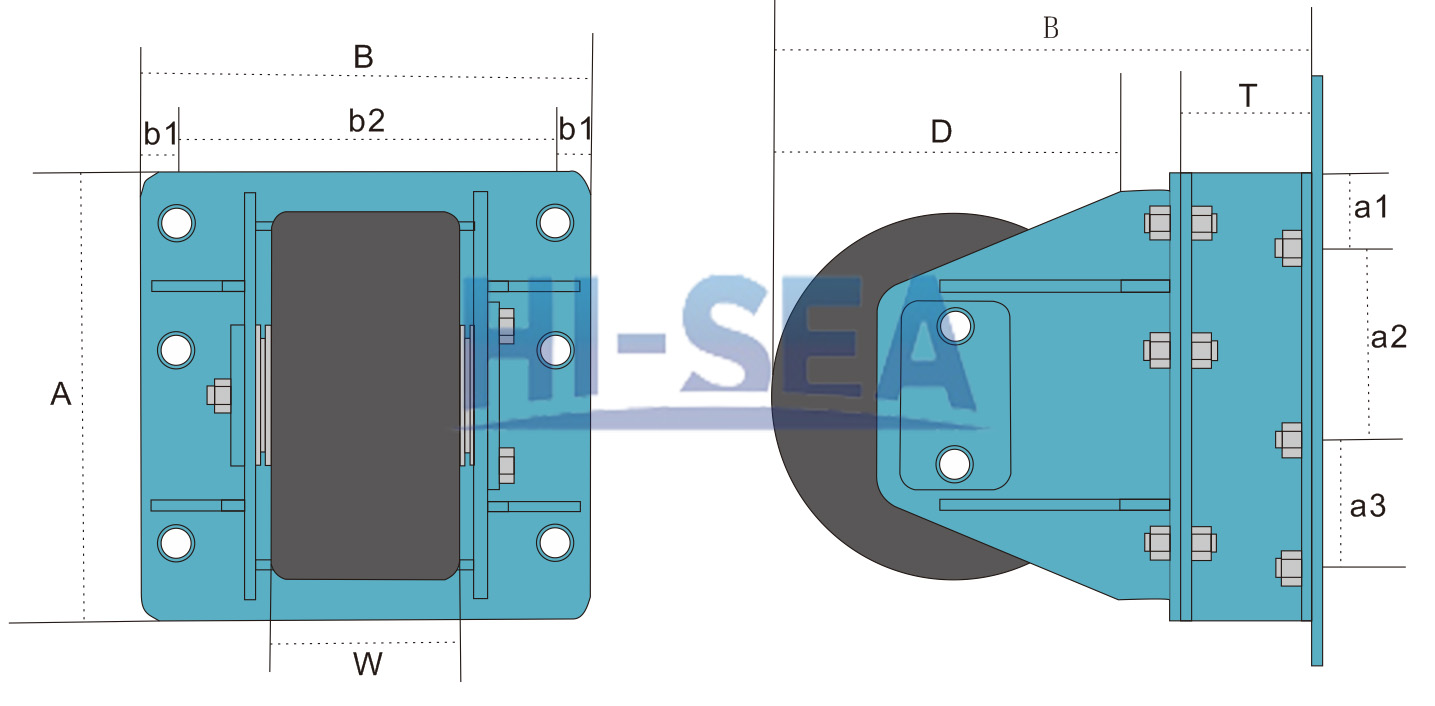

The model 770×450×350 is the largest standard size of cushion roller fender. We can look to the following drawing of cushion roller fenders. The fenders are made of two parts. One is the rubber roller part used for cushion and the other is the steel frame part used for supporting. The width and length of the supporting steel frame are 770mm and 725mm respectively, and the diameter and the thickness of the roller is 450mm and 350mm separately.

The main cushion part of cushion roller fenders is manufactured with high-quality rubber material which is elastic and wear-resistant. When the pile fenders move after being stroke, the rubber roller will rotate accordingly. This property ensures that the impacts can be reduced to the utmost and cushion roller fenders can serve for a long time and perform well in daily use.

Cushion roller fender is very easy to install. The steel frame is used to support the rubber roller and can help to install. The rubber rollers are pre-drilled with several anchor holes, so that the equipment can be easily mounted onto the target structures.

Cushion Roller Fenders Drawing and Dimensions:

| A |

B |

C |

D |

T |

W |

a1 |

a2 |

a3 |

b1 |

b2 |

Fixings |

| 770 |

725 |

690 |

450 |

200 |

350 |

120 |

300 |

300 |

70 |

585 |

6×M36 |

Funktionen:

- Very quiet when working

- Very resilient with high quality rubber material

- Maintenance-free bearings

- Reasonable energy absorption on berthing impacts

Anträge:

- Guide for pontoon pile

- Other floating structures