D rubber fenders are manufactured with high-quality rubber materials, designed into the D-shape profile with D hollow chamber. This design helps to reduce the reaction force and increase the energy absorption capability. As an excellent-performance type of rubber fenders, D rubber fenders are popularly used all over the world.

The model D400 rubber fenders are the second largest type of standard sizes. They are frequently applied to relatively large docks. The great physical properties such as wear-resistance make them endure long time of water erosion and maintain in duty for almost over ten years normally.

Given different dock structures and applicable scenarios, D rubber fenders have taken two installation methods in general, and one is mounting via pre-drilled holes, the other is installing with steel bars. This two can almost fit for all the dock structures. So they are definitely easy to install and replace while at the same time, they can provide excellent protection.

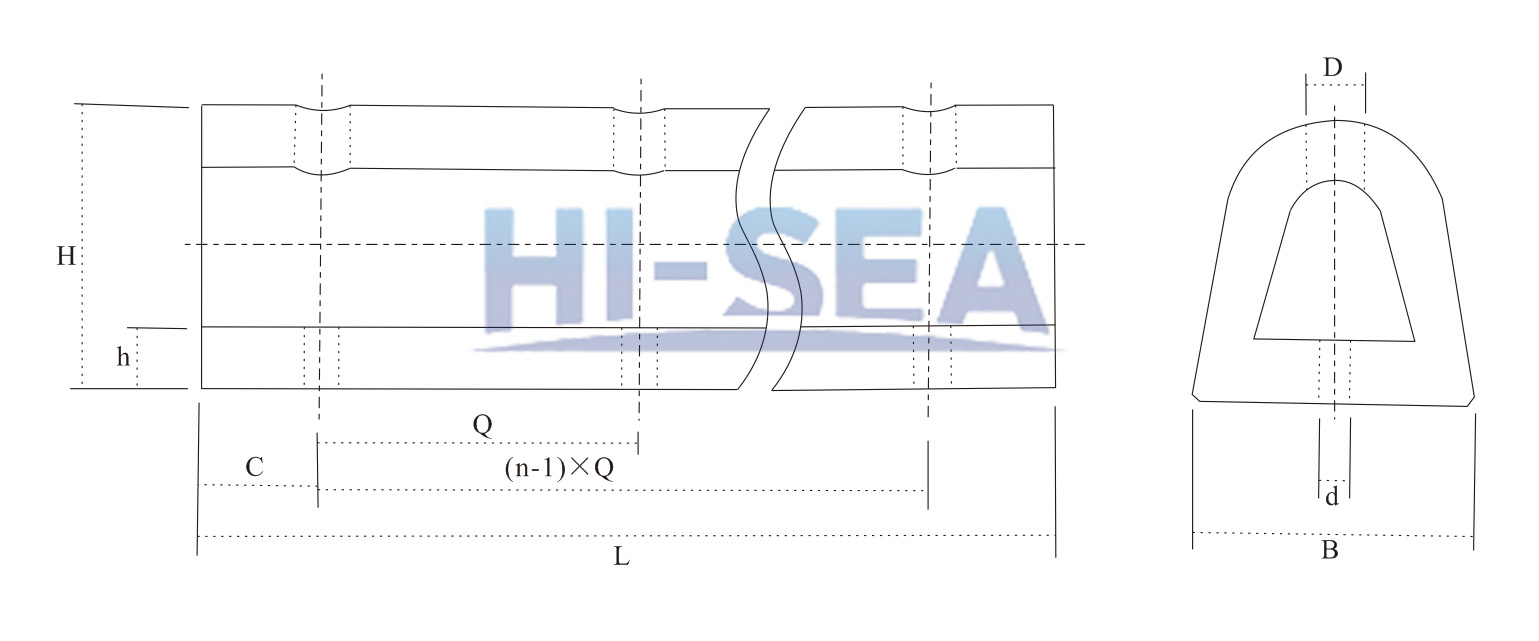

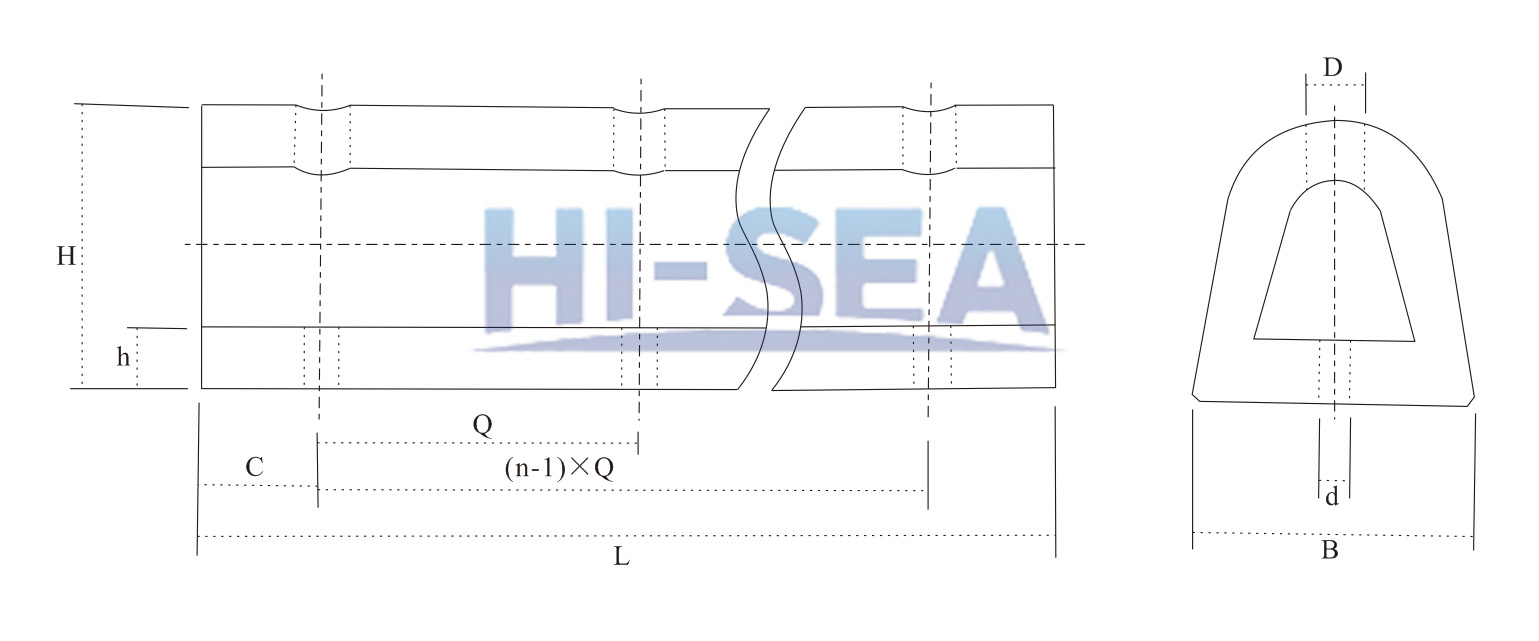

The D Rubber Fenders Drawing and Dimensions:

| Specifications |

H |

B |

L |

n |

Q |

C |

D |

d |

| D300×300×1000 |

300 |

300 |

1000 |

3 |

350 |

150 |

65 |

32 |

| D300×300×1500 |

1500

|

3 |

600 |

150 |

65 |

32 |

| D300×300×1500 |

4 |

400 |

150 |

65 |

32 |

| D300×300×1500 |

5 |

325 |

100 |

65 |

32 |

The Performance List of D Rubber Fenders:

| Model |

Rated Deflection(%) |

Performance |

| R(KN) |

Tolerance |

E(KN/M) |

Tolerance(%) |

| D300×300×L |

50 |

294.3 |

±10 |

11.8 |

±10 |

Features:

- Easy to install and replace

- Low maintenance

- Applicable for many areas including docks, wharves, and so on

- Wide range of standard sizes available

- High energy absorption and low reaction force

Sling Type Pneumatic Rubber Fenders(4500×12000)

Sling Type Pneumatic Rubber Fenders(4500×12000)