The D300×360 model of D rubber fender is a modified version of D300. With the change of height from 300mm to 360, this D rubber fender can provide higher energy absorption and lower reaction force. This design comprehensively considers the frequently used scenarios for D rubber fenders so that they can be applicable for more working areas.

D rubber fenders are manufactured with D-shape profile, usually designed into a rubber fender with D hollow chamber. The normal installation methods are pre-drilled mounting holes and steel bar mounting method. The two mounting methods makes the fenders available for different dock structures.

Years of application has proven the performance of D rubber fenders. As one of the most popular rubber fenders around the world, D rubber fenders has been being the first choice for many buyers day by day.

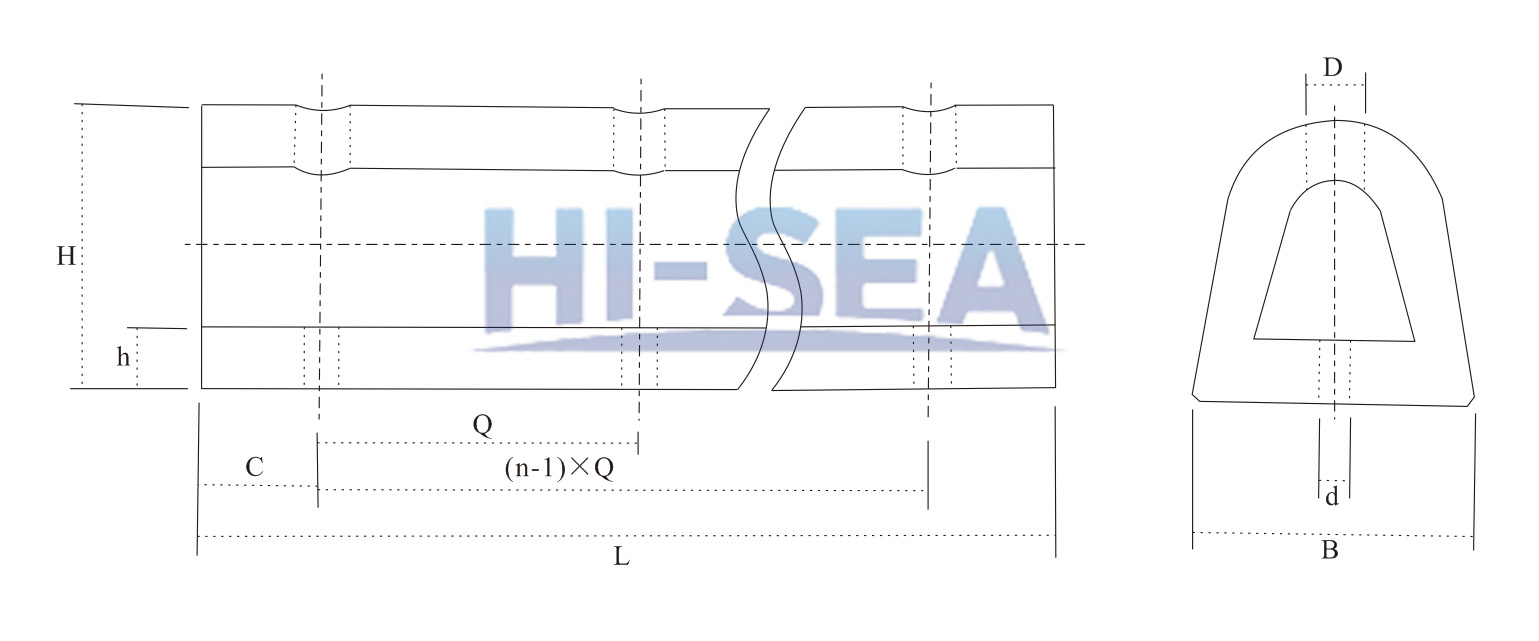

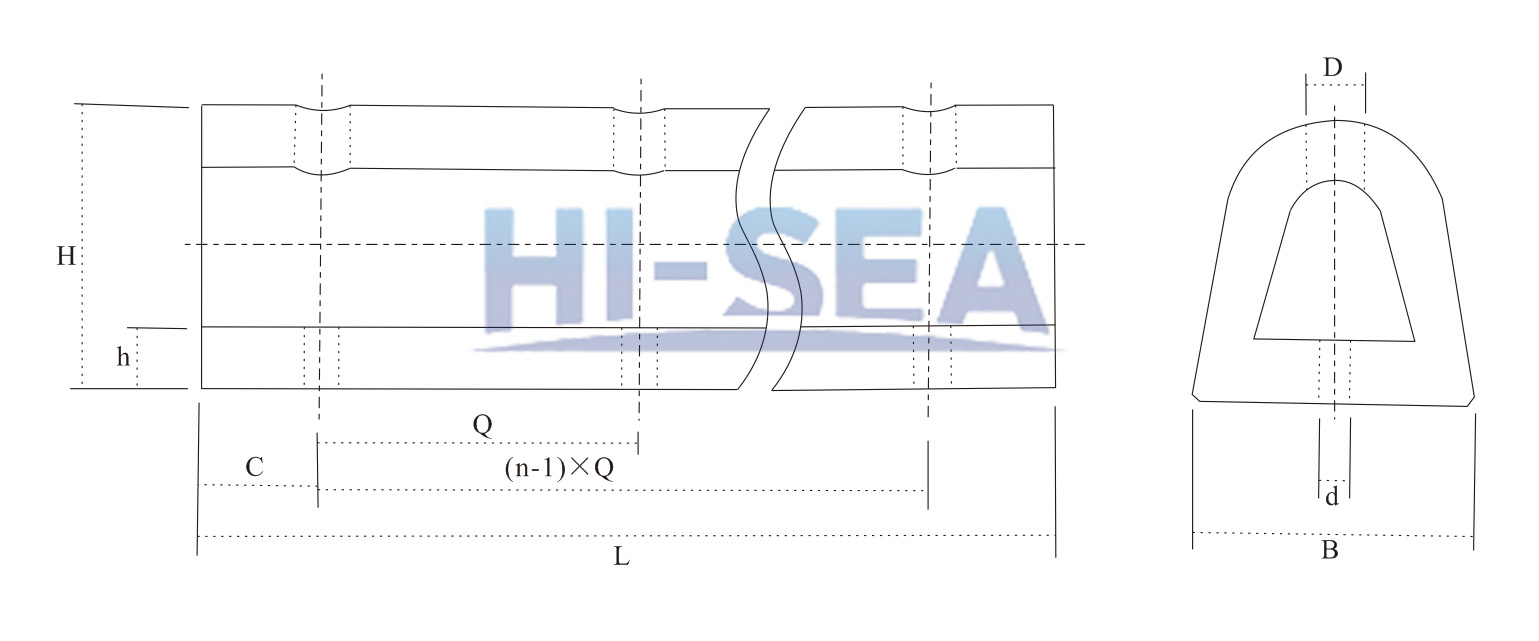

The D Rubber Fenders Drawing and Dimensions:

| Specifications |

H |

B |

L |

n |

Q |

C |

D |

d |

| D300×360×1000 |

300 |

360 |

1000 |

3 |

350 |

150 |

65 |

32 |

| D300×360×1500 |

1500 |

3 |

600 |

150 |

65 |

32 |

| D300×360×1500 |

4 |

400 |

150 |

65 |

32 |

| D300×360×1500 |

5 |

325 |

100 |

65 |

32 |

The Performance List of D Rubber Fenders:

| Model |

Rated Deflection(%) |

Performance |

| R(KN) |

Tolerance |

E(KN/M) |

Tolerance(%) |

| D300×360×L |

50 |

323.7 |

±10 |

13.7 |

±10 |

Features:

- Low maintenance

- Easy to install and replace

- High energy absorption and low reaction force

- Wide range of standard sizes available

- Applicable for many areas including docks, wharves, and so on

Sling Type Pneumatic Rubber Fenders(4500×12000)

Sling Type Pneumatic Rubber Fenders(4500×12000)