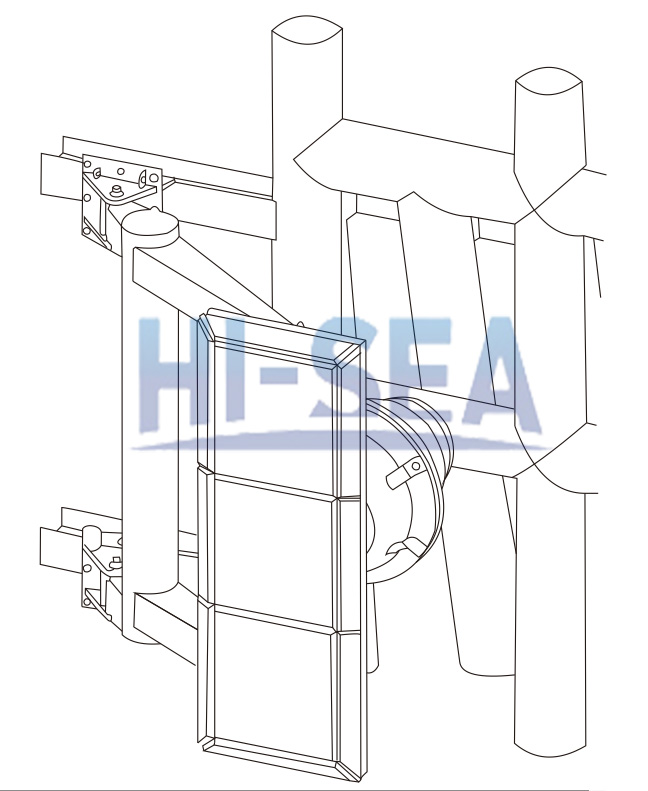

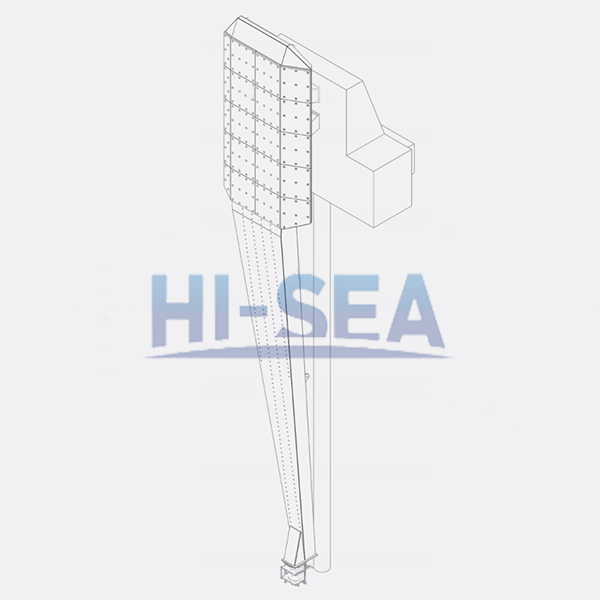

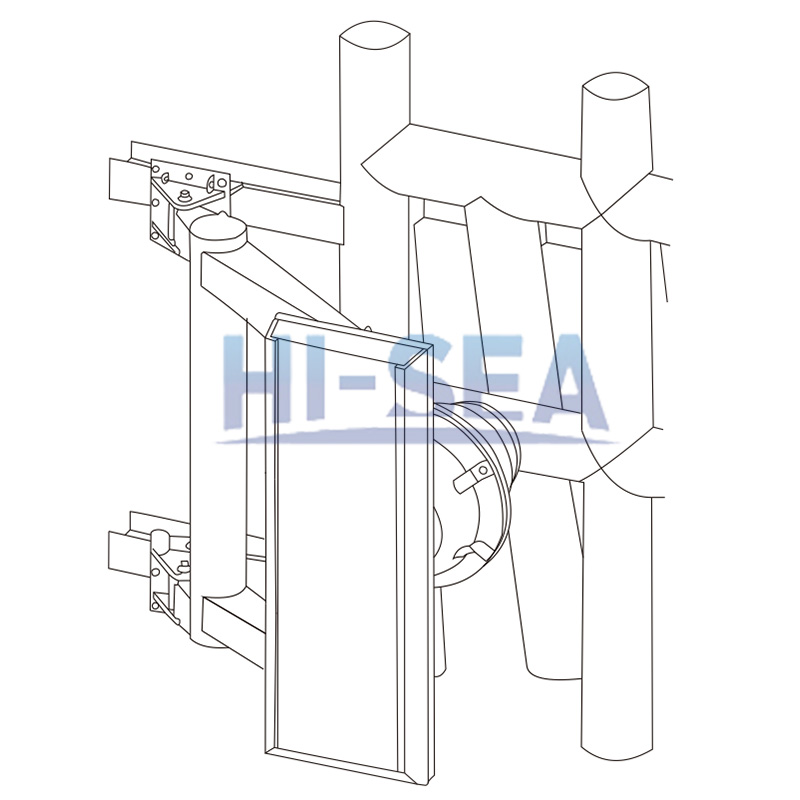

Installation of Parallel Motion Fender:

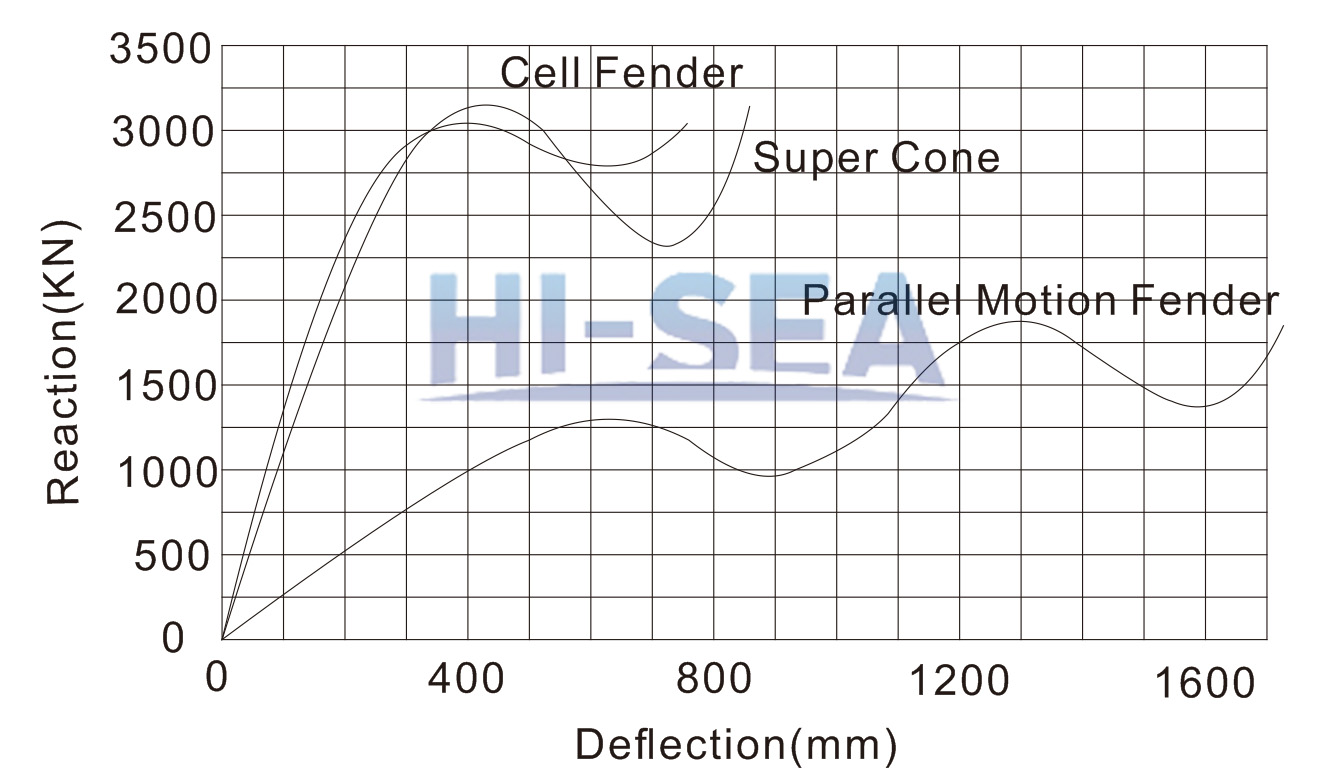

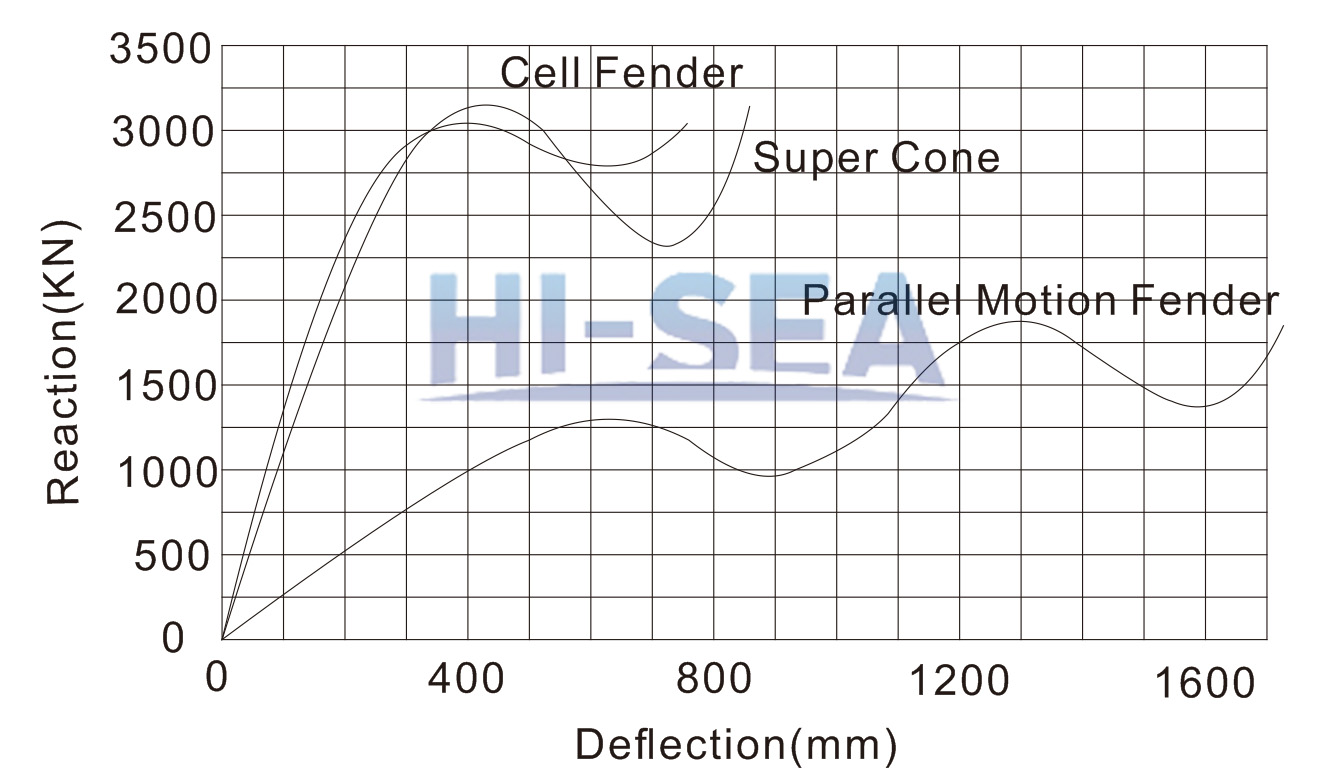

Comparison of PMF and Conventional Fenders:

| Type

|

E(KN/M) |

R(KN) |

ε20

|

| 0º |

10º |

20º |

RPD |

| Parallel Motion Fender

PMF1200(F3.1&F1.9) |

2186.6 |

2186.6 |

2186.6 |

1955.5 |

100% |

| Super Cone

2×SCN1200(F2.8) |

2182.2 |

2182.2 |

1612.6 |

3347.2 |

43% |

| Cell Fender

2×SCK1450(E3.0) |

2153.2 |

1901.3 |

1403.9 |

3381.2 |

37% |

|

NOTE: 1. ε20=Relative Efficiency at 20º angle compared to PMF. 2. Performance at RPD. 3. Performance PMF softer cone taken at 75% deflection.

|

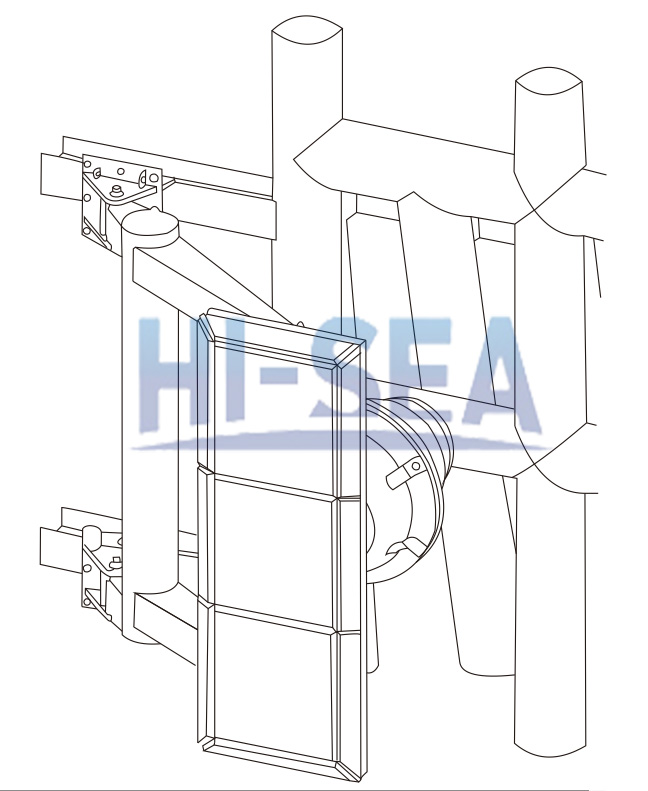

Applicaiton of Parallel Motion Fender:

Introduction:

Parallel motion fender is a highly customized designed fender system. The structure of the dock and other impact factors need to be considered comprehensively. But this unique fender system has structural features. Between the structure of the system and the panel restrains a swivel lever-arm is placed. This property makes it move only parallel to its mounting irrespective of the impact level and angle.

This large type of fender system has high energy absorption capacity and ultra low reaction force. In each angle, its performance will maintain. This will definitely help to lower down the hull pressure and provide safety for everyone people and properties involved to the utmost.

Identical energy absorption capacity at any impact level.

No second point of contact between a ship and a fender system.

Lower reaction force in comparison with the conventional fender systems.

Less hull pressure and lighter structures

Highly customized design fender

Sling Type Pneumatic Rubber Fenders(4500×12000)

Sling Type Pneumatic Rubber Fenders(4500×12000)