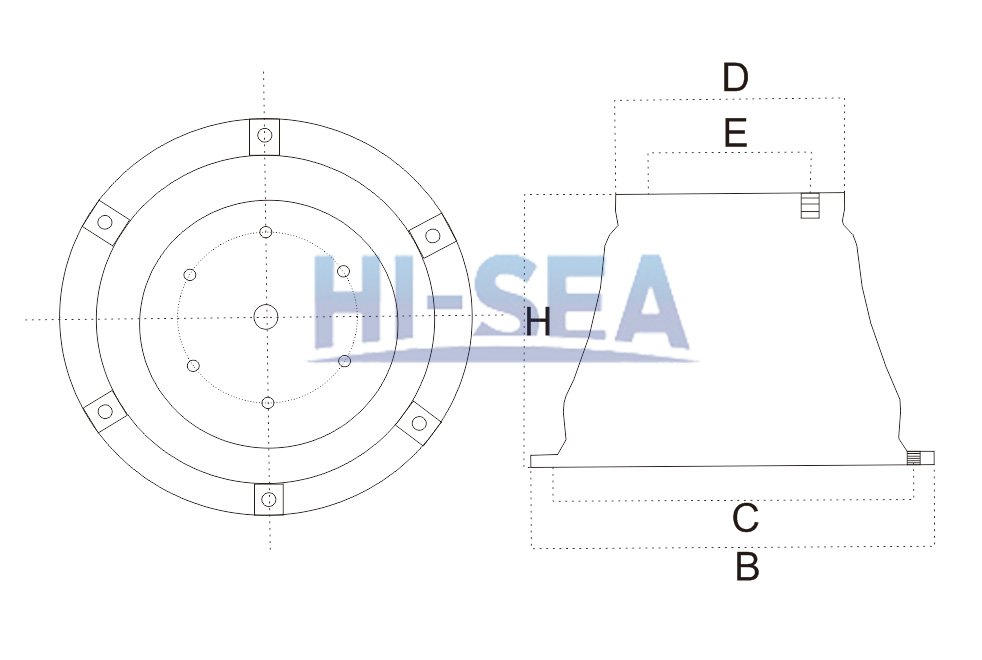

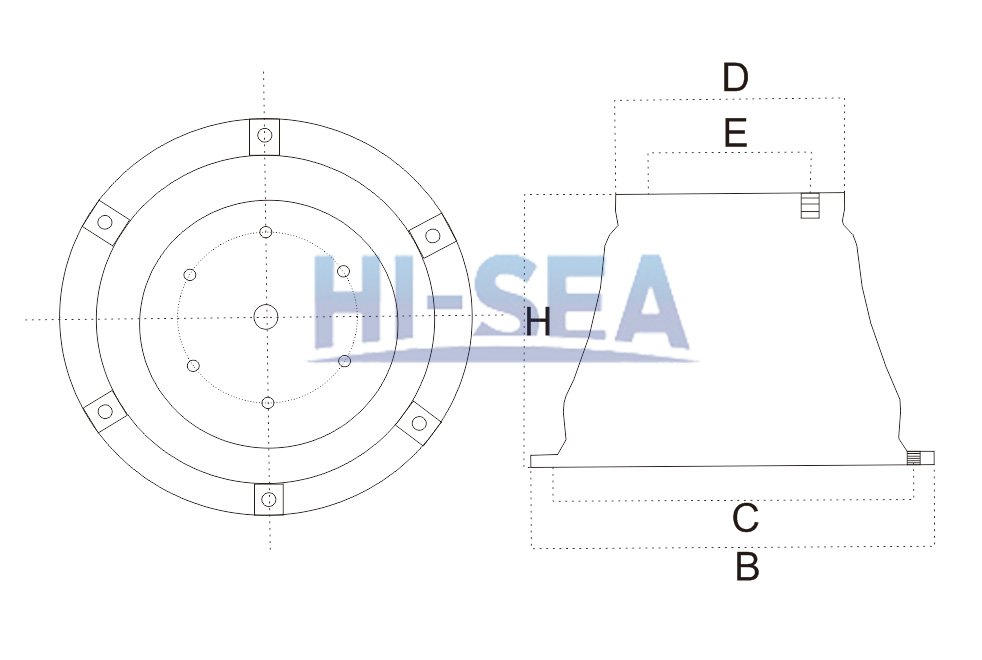

Cone Type Rubber Fender Drawing and Dimensions:

| SPECIFICATIONS |

H |

C |

B |

E |

D |

| CF 300H |

300 |

405 |

450 |

195 |

255 |

| CF 350H |

350 |

510 |

570 |

235 |

300 |

| CF 400H |

400 |

540 |

600 |

260 |

340 |

| CF 500H |

500 |

675 |

750 |

325 |

425 |

| CF 600H |

600 |

810 |

900 |

390 |

510 |

| CF 700H |

700 |

945 |

1050 |

455 |

595 |

| CF 800H |

800 |

1080 |

1200 |

520 |

680 |

| CF 900H |

900 |

1215 |

1350 |

585 |

765 |

| CF 1000H |

1000 |

1350 |

1500 |

650 |

850 |

| CF 1100H |

1100 |

1485 |

1650 |

715 |

935 |

| CF 1150H |

1150 |

1550 |

1725 |

750 |

977.5 |

| CF 1200H |

1200 |

1620 |

1800 |

780 |

1020 |

| CF 1250H |

1250 |

1700 |

1875 |

815 |

1062.5 |

| CF 1300H |

1300 |

1755 |

1950 |

845 |

1105 |

| CF 1350H |

1350 |

1850 |

2025 |

880 |

1147.5 |

| CF 1400H |

1400 |

1890 |

2100 |

910 |

1190 |

| CF 1450H |

1450 |

1960 |

2175 |

945 |

1232.5 |

| CF 1500H |

1500 |

2025 |

2250 |

975 |

1275 |

| CF 1550H |

1550 |

2095 |

2325 |

1010 |

1317.5 |

| CF 1600H |

1600 |

2160 |

2400 |

1030 |

1360 |

| CF 1800H |

1800 |

2625 |

2880 |

1190 |

1530 |

| CF 2000H |

2000 |

2920 |

3200 |

1710 |

1955 |

| CF 2250H |

2250 |

3285 |

3600 |

1930 |

2205 |

| CF 2500H |

2500 |

3650 |

4000 |

2150 |

2450 |

| NOTE (units:mm) |

The drawing and dimensions are for reference. Other specifications are also available. Please contact us for detailed information.

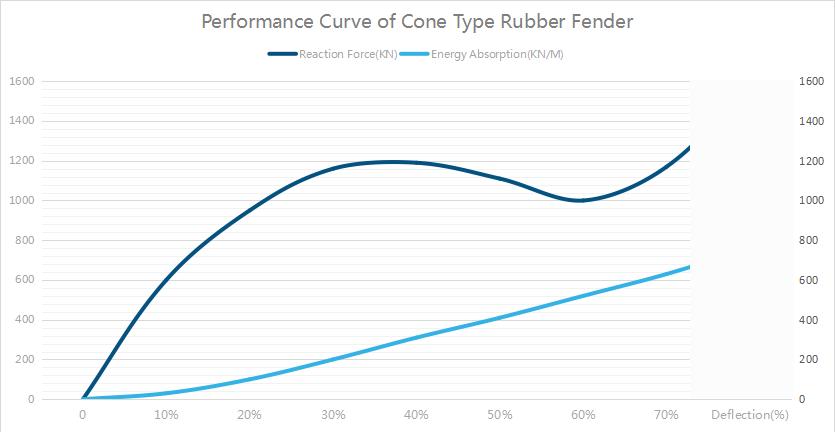

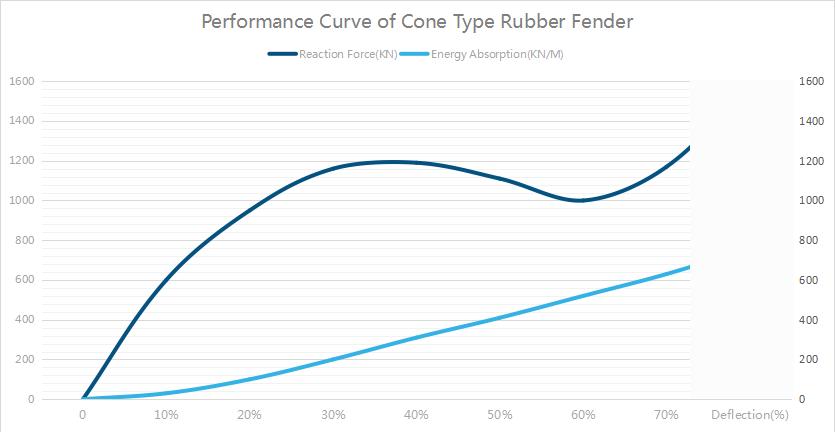

The Performance List of Cone Type Rubber Fender:

| SPECIFICATIONS |

R1 |

R2 |

R3 |

R4 |

| R(KN) |

E(KN/M) |

R(KN) |

E(KN/M) |

R(KN) |

E(KN/M) |

R(KN) |

E(KN/M) |

| CF 300H |

59 |

7 |

68 |

9 |

84 |

11 |

104 |

14 |

| CF 350H |

80 |

12 |

93 |

14 |

114 |

19 |

141 |

23 |

| CF 400H |

105 |

18 |

124 |

22 |

150 |

28 |

185 |

34 |

| CF 500H |

165 |

37 |

196 |

47 |

268 |

63 |

335 |

79 |

| CF 600H |

226 |

75 |

283 |

94 |

382 |

120 |

480 |

151 |

| CF 700H |

308 |

120 |

385 |

150 |

522 |

181 |

652 |

230 |

| CF 800H |

402 |

179 |

502 |

224 |

706 |

280 |

862 |

351 |

| CF 900H |

509 |

255 |

636 |

302 |

852 |

380 |

1028 |

480 |

| CF 1000H |

628 |

350 |

785 |

438 |

1078 |

530 |

1330 |

651 |

| CF 1100H |

800 |

405 |

949 |

482 |

1190 |

640 |

1480 |

830 |

| CF 1150H |

830 |

532 |

1040 |

665 |

1302 |

801 |

1620 |

920 |

| CF 1200H |

904 |

543 |

1106 |

680 |

1410 |

814 |

1746 |

1062 |

| CF 1250H |

981 |

684 |

1230 |

855 |

1530 |

975 |

1920 |

1270 |

| CF 1300H |

1120 |

740 |

1330 |

962 |

1660 |

1140 |

2120 |

1490 |

| CF 1350H |

1170 |

810 |

1430 |

1080 |

1760 |

1280 |

2230 |

1640 |

| CF 1400H |

1230 |

865 |

1510 |

1130 |

1804 |

1340 |

2400 |

1790 |

| CF 1450H |

1320 |

980 |

1650 |

1240 |

1923 |

1480 |

2580 |

1940 |

| CF 1500H |

1410 |

1110 |

1770 |

1342 |

2042 |

1620 |

2760 |

2090 |

| CF 1550H |

1510 |

1246 |

1890 |

1445 |

2162 |

1770 |

2950 |

2240 |

| CF 1600H |

1610 |

1340 |

1960 |

1540 |

2280 |

1902 |

3024 |

2385 |

| CF 1800H |

1912 |

1804 |

2401 |

2264 |

2950 |

2810 |

3700 |

3515 |

| CF 2000H |

2400 |

2674 |

2900 |

3340 |

3295 |

3791 |

4540 |

4610 |

| CF 2250H |

3030 |

3780 |

3670 |

4780 |

4100 |

5150 |

5496 |

6450 |

| CF 2500H |

3310 |

4603 |

3989 |

5752 |

4420 |

6190 |

6012 |

7990 |

| NOTE: RATED DEFLECTION 70%, TOLERCANCE±10% *REACTION FORCE(R) ENERGY ABSORPTION(E) |

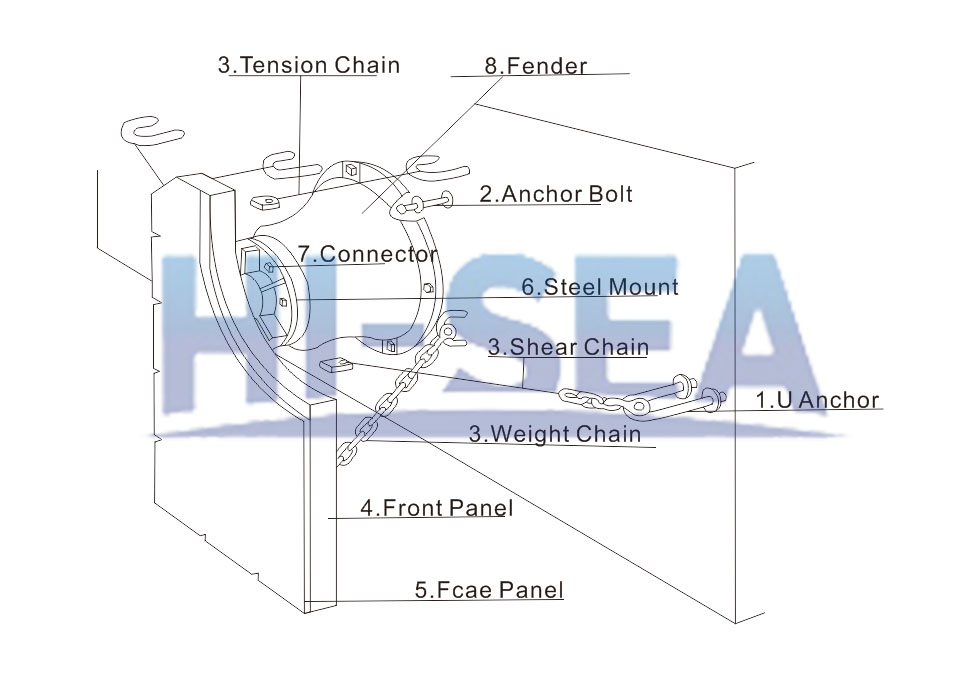

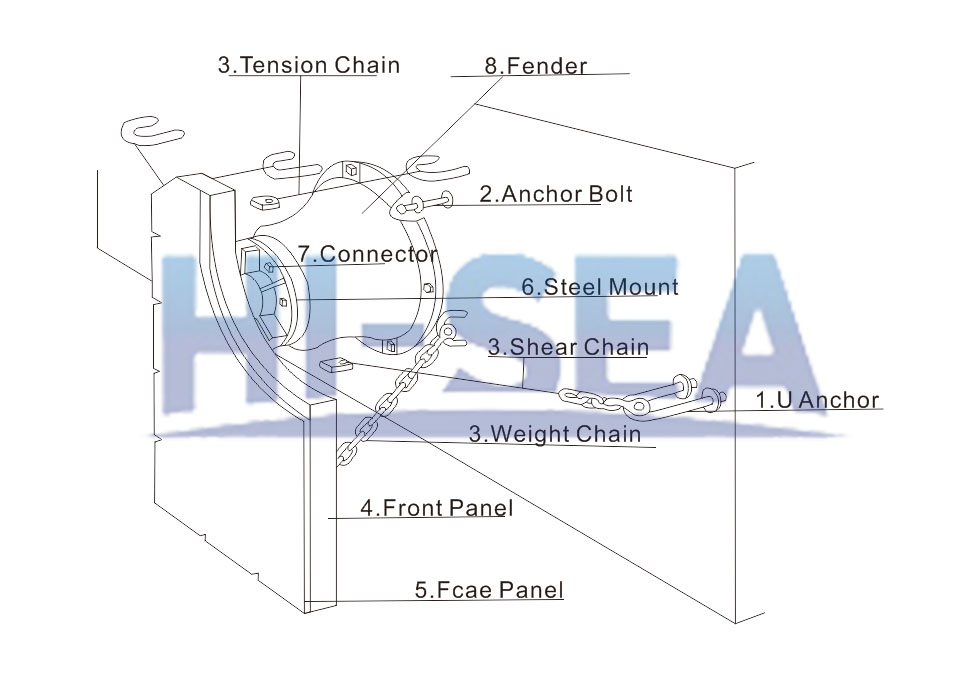

Installation of Cone Type Rubber Fenders:

Cone Type Rubber Fenders in Factory:

Application of Cone Type Rubber Fenders:

Introduction:

Cone type rubber fender is the third generation of cell fender. This structure design helps to lift the rated deflection from 52.5% to 70%, which means it is endowed with excellent energy absorption but low reaction force. Moreover, all cone fenders are single piece mouldings. Therefore, they have the most efficient performance compared to any other fender types. Cone fenders, in many cases, together with the frontal frame consisting of steel panel and UHMW-PE facing pad, are used successfully in many scenarios, including container & bulk terminals, oil & gas terminals, general cargo terminals and so on. When used in different types of docks, terminals, and quays, cone fenders can simplify the structure of them and lower down the construction costs.

Accessories and Fixings

- Anchors

- Anchor bolts and nuts

- Tension chains, shear chains, weight chains

- Steel mount

- Connectors(connecting steel mount and cone fender)

- Front panel

- Face panel

Sling Type Pneumatic Rubber Fenders(4500×12000)

Sling Type Pneumatic Rubber Fenders(4500×12000)