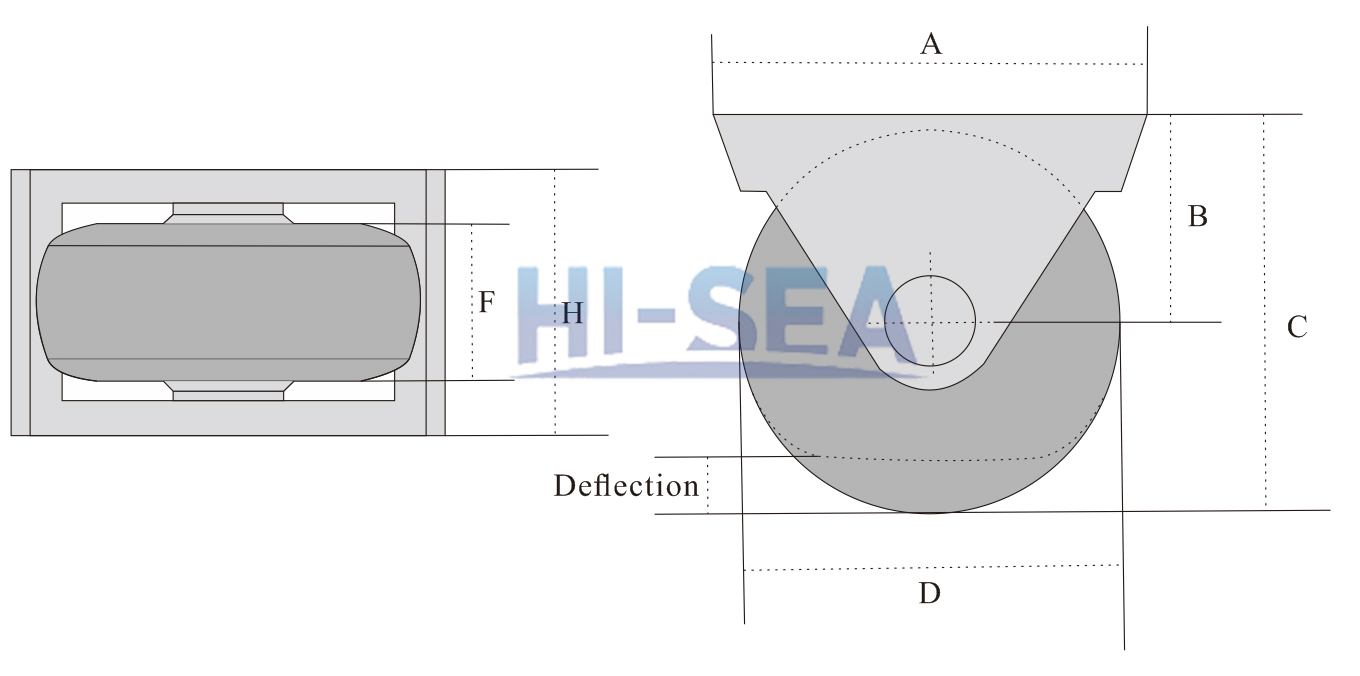

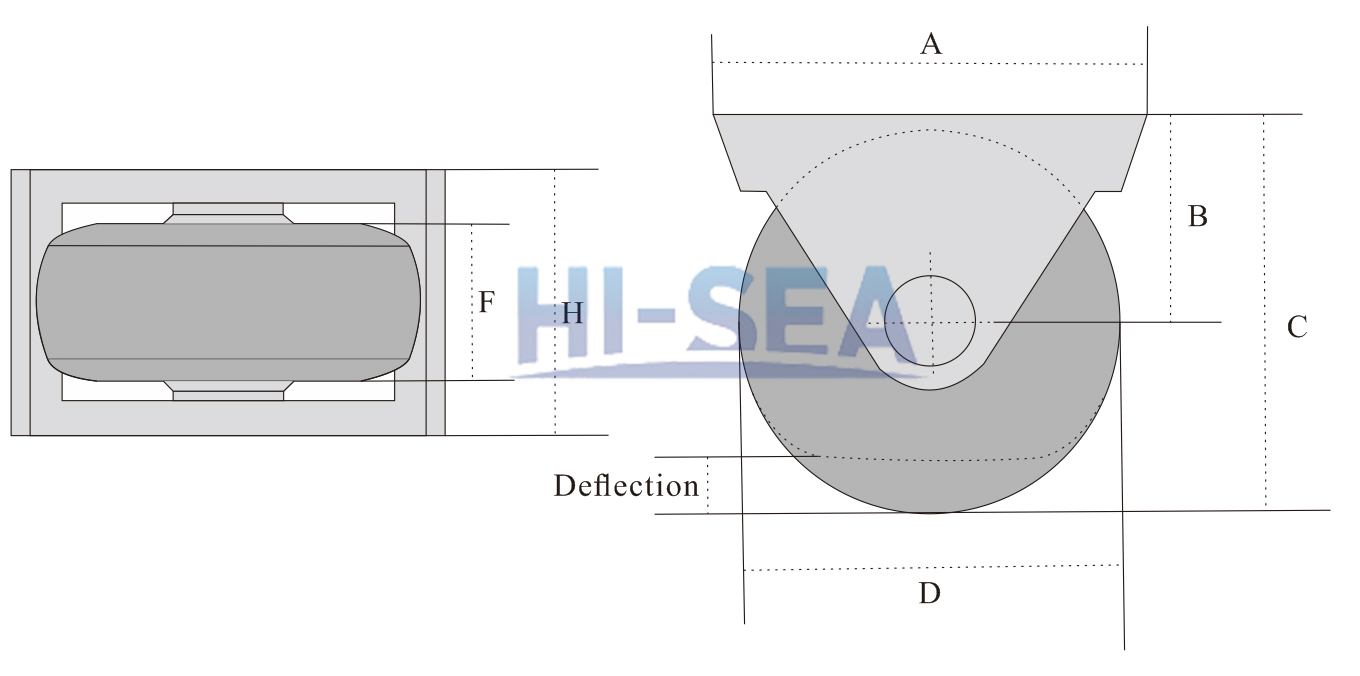

Roller fenders is a combination of two parts. One part is rubber roller used as cushion and the other is steel frame used as supporting part. The numbers of he model 1370×610 of roller fenders refer to the diameter and the thickness of the rubber roller respectively. The bottom length of the supporting frame is 1600mm and its height is 1000mm.

0ther fixed fenders normally are not as large as this type. For the applications of the roller fenders are easy to collide, larger and stronger rubber fenders are needed. The main part of roller fenders is the rubber roller, manufactured with high-quality and wear-resistant rubber material. The rubber roller is mounted onto an fixed axle supported by a special designed steel frame. And then, the frame can be easily installed onto the dock structures. By using these fender, friction and impacts can be reduced, for the rubber roller can rotate in a radius around the axle on berthing process.

Working as not only a cushion, but also a guide to berth, roller fenders are frequently set at the entrance of inland waterway channel, locks, dry docks and other narrow or exposed areas. And the installation positions are always somewhere near the dock corners.

Roller Fenders Drawing and Dimensions:

| A |

B |

C |

D |

H |

F |

Deflection |

| 1600 |

765 |

1450 |

1370 |

1000 |

610 |

205 |

Features:

- Guiding system for vessels’ berthing

- High energy absorption and reasonable reaction force

- Low friction due to fender rotation

- Multipurpose use

- Robust and resilient

Applications:

- Entrance to locks, dry docks and other narrow or exposed areas

- Dock corners

- Inland waterway channels

Sling Type Pneumatic Rubber Fenders(4500×12000)

Sling Type Pneumatic Rubber Fenders(4500×12000)