Cone rubber fender is the latest version of cells fenders. Cone fenders have extended the rated deflection and energy absorption capability to a new level. With 70% rated deflection and 72% maximum deflection, cone fenders decreased their reaction force. Moreover, the shear forces has also been decreased due to the conical profile.

The most frequently used models of cone rubber fenders are Cone500, Cone600, Cone700, Cone 800, Cone900, Cone1000, Cone1100, Cone1200, Cone1300, Cone1400, Cone1500.(View the detailed information and all specifications of Cone Fenders, please Click Here.)

Cone1300, Cone1400, and Cone1500 are relatively large sizes of cone rubber fenders. Assembled with frontal panel and UHMW-PE face pad, cone fenders can carry out heavy duties. These large sizes fenders are usually used for large terminals and docks. Large vessels can be well protected when berthing on the docks installed with large cone fenders.

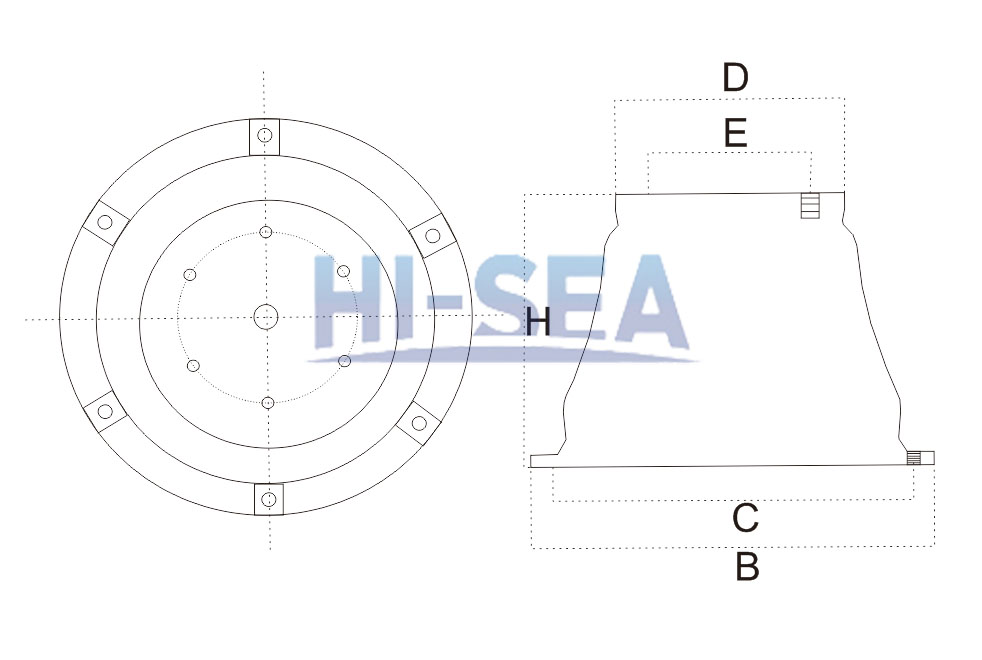

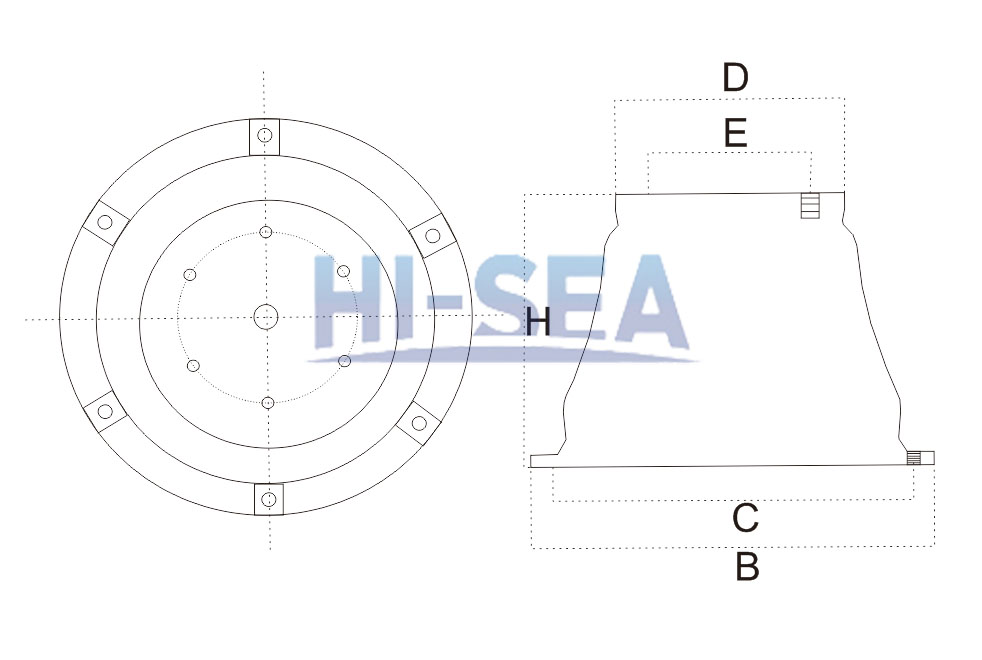

Cone Rubber Fenders Drawing and Dimensions:

| SPECIFICATIONS |

H |

C |

B |

E |

D |

| CO 1300H |

1300 |

1755 |

1950 |

845 |

1105 |

| CO 1400H |

1400 |

1890 |

2100 |

910 |

1190 |

| CO 1500H |

1500 |

2025 |

2250 |

975 |

1275 |

Performance List of Cone Rubber Fenders:

| SPECIFICATIONS |

R1 |

R2 |

R3 |

R4 |

| R(KN) |

E(KN/M) |

R(KN) |

E(KN/M) |

R(KN) |

E(KN/M) |

R(KN) |

E(KN/M) |

| CO 1300H |

1120 |

740 |

1330 |

962 |

1660 |

1140 |

2120 |

1490 |

| CO 1400H |

1230 |

865 |

1510 |

1130 |

1804 |

1340 |

2400 |

1790 |

| CO 1500H |

1410 |

1110 |

1770 |

1342 |

2042 |

1620 |

2760 |

2090 |

Installations:

Refer to he detailed installation graph please refer to Cone Type Rubber Fender (Click Here). The following fixings and accessories are needed for installation:

- Frontal panel: reducing face pressure to protect fenders and vessels

- Face pad: reducing friction to non-mark the vessel hull

- Pre-built-in bolts and nuts: fastening fenders onto docks

- Pre-built-in U anchors: holding chains

- Link bolts and nuts: connecting fender and frontal panel and other accessories

- Weight chain: supporting the frontal panel

- Tension chain: limiting fender deflection in avoid of sagging

- Shear chain: preventing fender system from shear deflection

Ps: Customers can design their own fender systems with cone fenders.

Applications:

- Heavy duty docks and terminals for large vessels berthing

Sling Type Pneumatic Rubber Fenders(4500×12000)

Sling Type Pneumatic Rubber Fenders(4500×12000)